- Overview

- Main Parameters

- Control System Function

- Recommended Products

Technical Specification

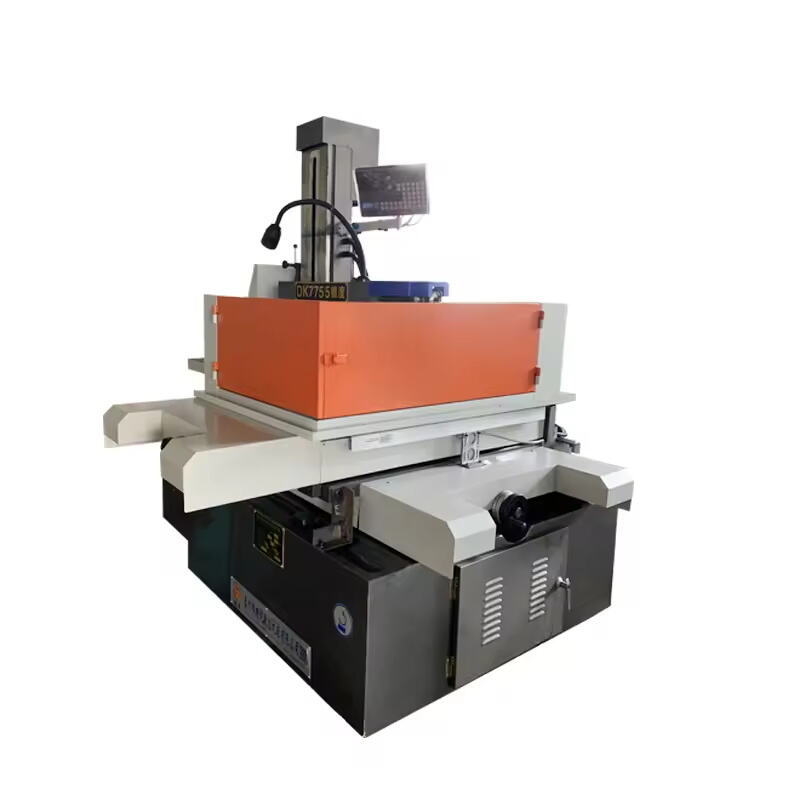

Machine Model: DK7755 CNC EDM Wire Cutting Machine

| Item | Unit | Parameter |

| X-axis | mm | 550 |

| Y-axis | mm | 650 |

| Tabletop Dimensions | mm | 1000 × 650 |

| Maximum Load | kg | 800 |

| Maximum Cutting Taper | °/mm | 3°/6° |

| Maximum Cutting Workpiece Thickness | mm | 500 |

| Electrode Wire Diameter | mm | φ0.12~φ0.18 |

| Optimal Machined Surface Roughness | μm | Ra ≤ 2.5 |

| Machining Accuracy | According to GB7926-2005 Standard | |

| Working Fluid | Dedicated working fluid for wire cutting (DX-1, DX-4, Nanguang-1) | |

| Stepper Motor | – | 90BF006 |

| Maximum Cutting Speed | mm²/min | 150 |

| Required Power Supply | KVA | 2 (3-phase ~380V, 50Hz) |

| Weight | kg | 1800 |

| Overall Dimensions | mm | 2100×1940×1780 |

| Programming & Control Software | – | HL Integrated Programming & Control Software |

| CNC Cabinet | – | Upright Cabinet |

2. Control Cabinet Function Description

| No. | Function Description | Remarks |

| 1 | Integrated programming and control software | |

| 2 | Graphical tracking | |

| 3 | Arbitrary angle rotation | |

| 4 | Symmetrical machining | |

| 5 | Wire break protection | |

| 6 | Automatic shutdown upon program completion | |

| 7 | USB read/write functionality | |

| 8 | Four-axis coordinated cutting | |

| 9 | Automatic retraction on short-circuit | |

| 10 | Forward and reverse machining | |

| 11 | Machining simulation |

| No. | Accessory |

| 1 | Work Light |

| 2 | Simple Fixture |

| 3 | Electrode Wire Vertical Alignment Device |

| 4 | Hand Lever |

| 5 | Wire Tensioner |

| 6 | Working Fluid System |

| 7 | Worktable Splash Guard |

| No. | Documentation |

| 1 | Packing List |

| 2 | Factory Quality Inspection Report |

| 3 | One Copy of the System Operation Manual |

| 4 | One Copy of the Machine Tool User Manual |

- From the date of delivery, the supplier provides a one-year mechanical warranty. Under normal operating conditions, the supplier is responsible for free maintenance and replacement of spare parts; however, consumable parts, wear parts, and tools are not covered under the warranty.

- After the one-year warranty period, the supplier will provide the necessary spare parts for repairs and offer repair services at reasonable charges.

The supplier shall provide free on-site training for 1–2 technical personnel at supplier’s site, with a duration of 1 to 2 days.

| No. | Item | Training Content |

| 1 | Programming | Instruction on programming techniques |

| 2 | Operation | Introduction to overall machine structure, startup procedures, and control panel key functions |

| Program call-up, detailed operation instructions | ||

| Operational precautions and safety measures | ||

| 3 | Mechanical Maintenance | 1) Overview of mechanical structures: |

| – Structure of X, Y, Z, U, and V axes | ||

| – Hydraulic and lubrication system structure | ||

| 2) Common mechanical issues and maintenance: | ||

| – Wire breakage handling procedures | ||

| 4 | Electrical Maintenance | 1) Identification of common electrical components and symbols |

| 2) Basic electrical knowledge introduction | ||

| 3) Explanation of machine electrical control diagrams | ||

| 4) Troubleshooting of common electrical faults | ||

| 5 | Testing | Practical hands-on testing and machine operation verification |

| Name | Origin (Manufacturer) | Remarks |

| Control System | ||

| x8 Control System / AutoCAD Control System | – | |

| Mechanical Parts(optional) | ||

| Casting | Domestic | HT200 resin sand |

| Ball Screw Pair | Domestic: Shaanxi Qishan | Grade P3 |

| Guide Rail | Domestic: Bearing steel | Quenched |

| Roller | Domestic: Shanghai Danli | |

| Bearing | Domestic: Harbin (Grade P5); Japanese: NSK | |

| Electrical Parts | ||

| AC Contactor | Siemens | |

| Relay | Omron | |

| High-Frequency Power Tube | Imported from Japan | |

| Transformer | Wuxi | |

| Stepper Motor | Changzhou Songya | |

| Others | Japan, Taiwan, Joint Venture | |