- Overview

- Recommended Products

standard fitting |

Industrial 27" LED display and WINDOWS10 system controller |

Intelligent high efficiency wire cutting discharge power supply |

Full speed high AC (alternating current) non-electrolytic power supply |

Refined circuit (Ra0.5um) |

Automatic correction of copper wire vertical instrument |

X and Y axis automatic oil feeding device |

Internal and external corner control function |

RJ45 and USB drive reading device |

cooling-water machine |

Selection configuration: |

380V voltage regulator |

Mechanical structure of CNC wire cutting machine

✦ The mechanical body is cast with high rigidity cast iron, and the working table is fixed

✦ X and Y axes are driven by linear motor

✦ U, V and Z axes use AC servo motors

✦ Windows 10 system controller and window interface

✦ Stable and high-speed automatic threading system (optional)

✦ High efficiency line cutting discharge power supply

✦ 1U screen display resolution

✦ High precision corner deceleration function

✦ Processing liquid temperature control system

CNC controller architecture

✦ Windows 10 window version interface

✦ 27-inch LED HD display

✦ 64-bit industrial computer with 8GB of memory

✦ Use industrial-grade 64GB SSD

✦ Use USB drives to access data

✦ RJ-45 network data access function.

✦ It has manual box operation

✦ The mouse and keyboard control the screen

✦ 2D/3D display of cutting patterns

✦ Anti-jamming technology

basic machine

specifications and models |

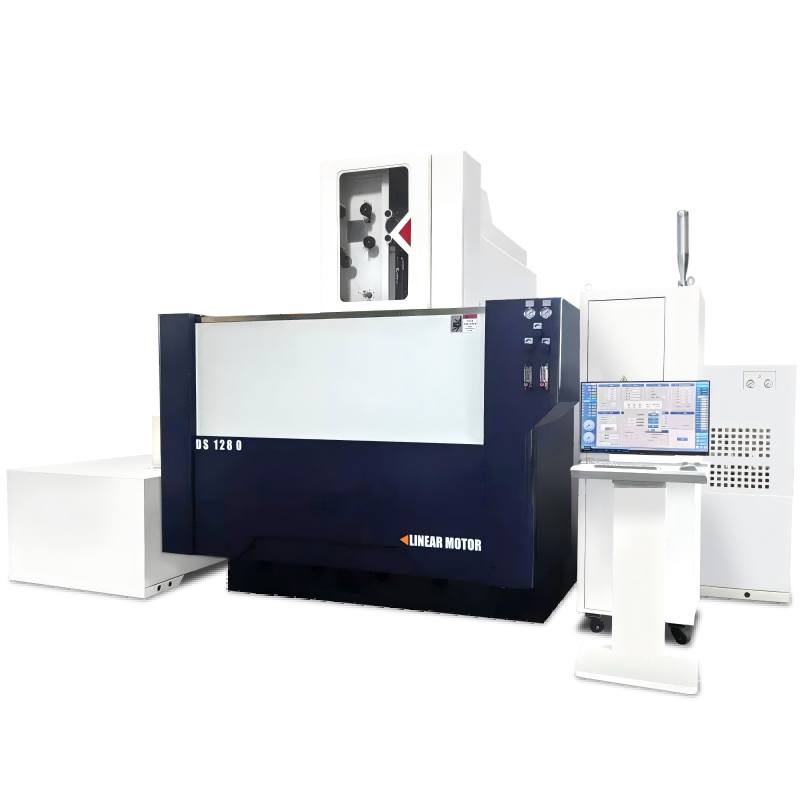

DS1280 |

X/Y axis stroke |

1200×800 mm |

U-V shaft stroke |

200×200 mm |

Z-axis stroke |

500mm (water immersion processing height 495mm) |

Maximum processing component size |

1700x1250mmx495mm |

Maximum workpiece load weight |

5000KG |

The height of the workbench above the ground |

995~1030 mm |

Number of shafts in the program |

5 axes (X, Y, Z, U, V) |

Maximum walking speed |

1500.0mm/min |

Processable wire diameter |

0.15 - 0.3mm |

Maximum load bearing weight of wire shaft |

10.0KG |

Maximum line tension |

0.5 - 2.4KG |

Fastest line closing speed |

330mm/sec |

Maximum taper machining angle |

+/-15° /80mm requires your own wide-angle eye mask |

Mechanical weight |

10000 kg |

Mechanical dimensions |

4650mmx3700mmx2550mm |

Mechanical color |

White and steel blue |

Maximum power consumption |

18KVA |

Z-axis ball screw |

Japan THK |

U-axis ball screw |

Japan THK |

V shaft ball screw |

Japan THK |

X-axis linear slide rail |

Japan THK |

Y linear slide rail |

Japan THK |

Z linear slide rail |

Japan THK |

U linear slide rail |

Japan THK |

V linear slide rail |

Japan THK |

X-axis linear motor |

straight-line drive |

Y-axis linear motor |

straight-line drive |

Z-axis AC servo motor |

400W Japan Panasonic brand |

U-axis AC servo motor |

400W Japan Panasonic brand |

V-axis AC servo motor |

400W Japan Panasonic brand |

Water tank system

specifications and models |

DS1280 |

Water tank capacity |

Immersion type / 2700 litres |

Net weight of tank |

Immersion type / 1100 kg |

Filter paper model |

replaceable filter paper mesh |

Water resistance |

The water tank contains an anion filter |

Filter tank capacity |

Immersion / 14 litres |

Water temperature control |

External cooler |

power box

specifications and models |

DS1280 |

Maximum operating current value |

25 A |

Pulse control power supply box |

Best frequency control system |

power input |

Three-phase input 380V-input frequency 50/60HZ |

CNC controller |

Window CE version system with multi-task real-time transmission software |

User memory space |

8GB of memory |

Storage device |

64GB SSD |

Input interface |

RJ-45 network access keyboard + mouse /U disk |

display device |

27-inch LED-LCD screen |

Accept glyphs |

Text/number/symbol |

Keyboard type |

Standard keyboard |

Coordinate control mode |

Incremental/absolute |

maximum input |

± 9999.999 |

User processing condition parameters |

1000 sets of parameter control |

Maximum available positive correction value |

1,000 groups |

Maximum number of rows to read |

N00000 to N99999 |

Maximum number of secondary subprogrammes |

8 |

Coordinate numbers |

6 |

Can be equal to the number of rotating shafts |

four-axis |

Minimum input unit |

1 µm |

Fastest air speed |

max. 1500.0 mm/min |

Position the drivetrain |

Equipped with optical scale full closed circuit control mode (optional) |

Drive transmission system |

servo drivers |

Guide screw back clearance compensation |

XYUV shaft/back gap compensation/Pitch compensation |

Program editing |

Background editing, program simulation and simulation can be synchronized during processing |

GD |

XY plane and UV plane 3D image simulation output |

Network functions |

RJ-45 network access function |

Soft-spoken

specifications and models |

DS1280 |

Interpolation correction mode |

"Straight line/arc |

program checkout |

Dibodi develops interpreters and compilers |

Maximum acceptable file capacity |

Each procedure 1 MB (about 1,000,000 characters) |

Consumption management prompt function |

Filter paper/conductive plate/filter paper/anion/diamond eye mask/electrode copper wire usage time |

Date specifications |

Year/Month/Day |

Program editing function |

Insert/cover, cut and paste blocks, search, replace, reply |

correcting feature |

Find the function/ find the center of hole/ find the center of circle/ find the Angle |

Sub-process control |

M98,M99 |

Graphic enlargement function |

0.001 to 1000 times |

Auxiliary keys |

Soft pad-assisted buttons |

Graphics path detection function |

Give an alarm when the NC code is entered incorrectly |

specifications and models |

DS1280 |

Coordinate setting |

Manual/automatic vertical correction |

Coordinate recording |

G54~G59 coordinate positioning/coordinate recording function |

correcting feature |

Find the edge, find the center of the groove, find the center of the hole, three points to determine the center of the circle, spark alignment, find the Angle, seek the mechanical zero point, taper processing parameter correction |

Numerical functions |

M a sign or object indicating number , |

document function |

Create files/stores files, delete files, rename files |

edit function |

Select, delete, insert/cover, block move/cut/paste, find, replace, etc |

External connectivity |

RJ45 output/input, USB, |

Mapping function |

Draw to set input Flag input File selection Cut plane draw Save drawing file |

Processing/Background NC program editing function |

Editing, drawing, revising |

Process the screen display |

Graphics, machining status display, mechanical status display, selected coordinates display + real-time machining curve |

Remote monitoring system |

Cutting coordinate display/cutting speed observation |

Maintenance screen |

Statistics on the use of consumable parts |

All coordinates are displayed |

The distance of each axis from the zero point coordinate or reference coordinate |

NC conditions are set |

Parameter processing, correction value, taper setting |

Cutting setup |

Condition parameters, drive parameters, auxiliary setting parameters |

Transmission Settings |

Mouse, keyboard, network connection |

( blank below )