- Overview

- Recommended Products

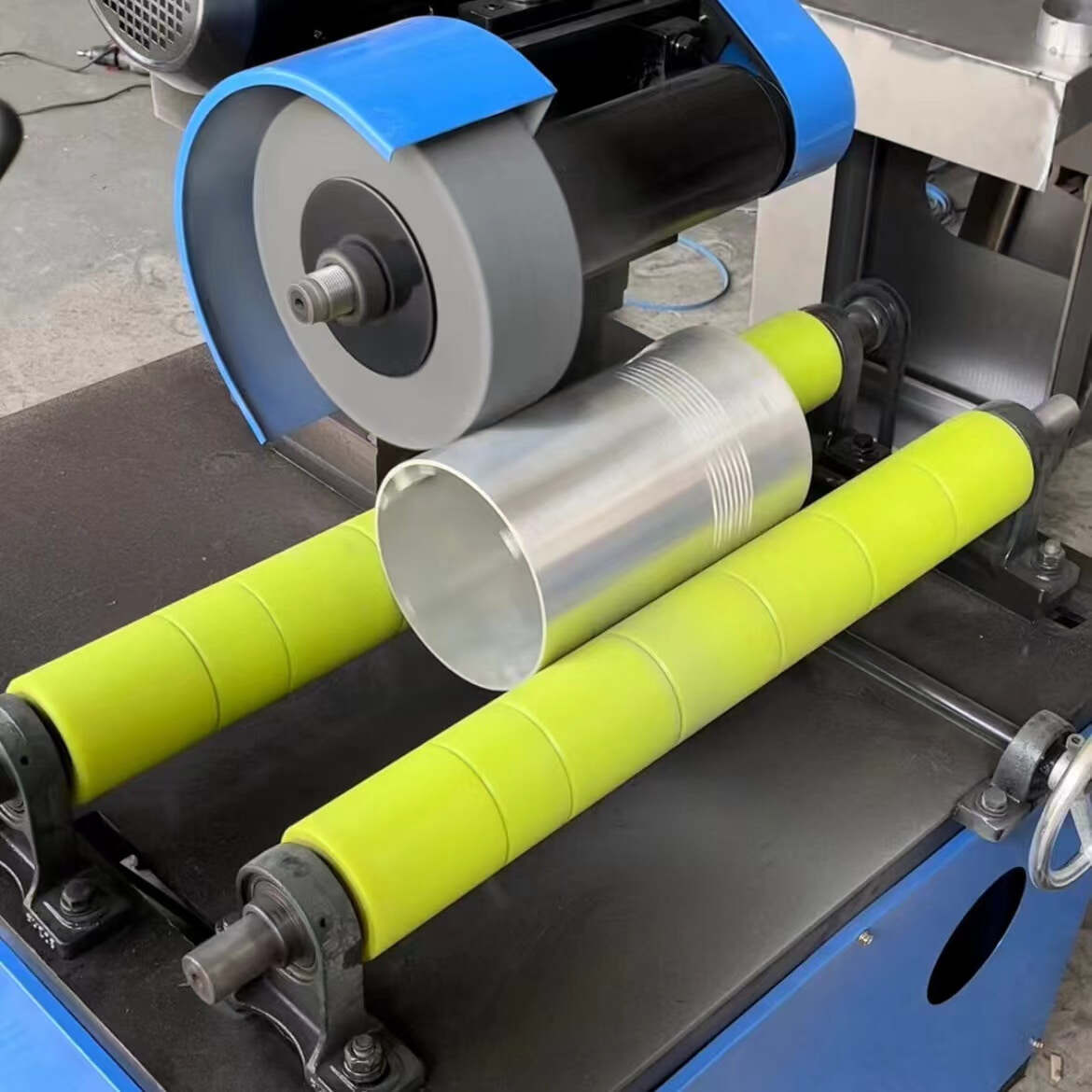

Product Introduction:

The outer circle polishing machine is independently developed by our factory's technical personnel based on market demand. This machine has the characteristics of high efficiency, high smoothness, and the ability to choose various grinding tools. It is mainly used for hardware; Electroplating, steel wood furniture, standard parts, automotive parts and other manufacturing industries, can polish, grind, and remove oxide skin on the outer surface of various equal diameter shafts, rods, stainless steel pipes, boiler pipes, high-precision pipes, titanium alloy rods, hydraulic rods for construction machinery, shock absorber rods for automobiles and motorcycles, valve rods, oil field pumping rods, various metals, non-metallic rods, pipes, plastics, rubber pipes, aluminum pipes, spinning machine rods, and various wire fittings, Rust removal, bright polishing, mirror polishing.

Working principle:

Using a grinding wheel (Chiba wheel/Polishing wheel) as the grinding tool, using typical cylindrical grinding technology, working on the material, particle size, softness and hardness of the grinding wheel (Chiba wheel/Polishing wheel), the contact method can achieve rough grinding, fine grinding, and polishing.

The main parameters of the machine

SIZE |

101*101*141CM |

Weight |

300KG |

Motor power |

4KW |

voltage |

380V(Other voltages can be customized) |

Machining diameter |

30-220CM |

Working length |

Unlimited length |

Processing speed |

0-12M/min(adjustable) |

Motor speed |

2800r/min |

Polishing consumables specifications |

250*32*40/80mm |

Usage:

The use of new machines:

1. Connect to three-phase 380V power supply

2. Test the machine's forward and reverse rotation in the direction of the arrow

3. Insert the workpiece and adjust the distance between the grinding head and the guide wheel to be exactly the same as the diameter of the workpiece.

4. Turn on the start switch and insert the workpiece for processing.