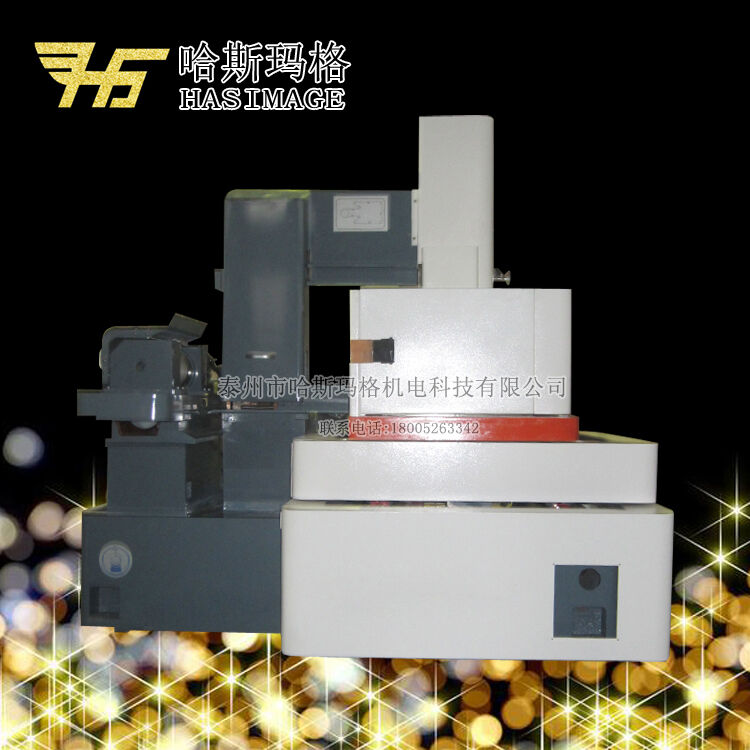

wire cut edm price

Wire cut EDM price represents a crucial consideration in modern manufacturing, encompassing both the initial investment and operational costs of Wire Electrical Discharge Machining technology. The pricing structure typically includes the machine cost, ranging from $35,000 for basic models to over $200,000 for advanced systems, along with operational expenses such as wire consumption, power usage, and maintenance. These machines utilize a thin metal wire as an electrode to cut through electrically conductive materials with extreme precision, achieving tolerances as fine as ±0.0001 inch. The technology employs electrical discharges to remove material through a series of controlled sparks, making it ideal for creating complex shapes in hardened materials. The price point varies significantly based on factors such as cutting speed capabilities, maximum workpiece dimensions, wire diameter options, and automation features. Modern wire EDM systems often include advanced CNC controls, automatic wire threading, and sophisticated programming capabilities, which influence the overall cost. When considering wire cut EDM pricing, it's essential to factor in both the immediate purchase price and long-term operational costs, including consumables, maintenance requirements, and potential productivity gains.