Mastering Precision Engineering Through Advanced EDM Drilling Technology

The manufacturing industry has witnessed remarkable advancements in precision engineering, with EDM drilling emerging as a cornerstone technology for creating microscopic holes with unprecedented accuracy. This sophisticated machining process uses electrical discharge to remove material, enabling the production of incredibly small, precise holes in even the most challenging materials. As industries push the boundaries of miniaturization, EDM drilling continues to revolutionize how we approach micro-hole creation in modern manufacturing.

EDM drilling has become indispensable in industries ranging from aerospace to medical device manufacturing, where precision and reliability are paramount. The technology's ability to create holes as small as 0.1mm in diameter while maintaining exceptional accuracy has made it the go-to solution for complex manufacturing challenges.

Understanding the EDM Drilling Process

Core Principles of Electrical Discharge Machining

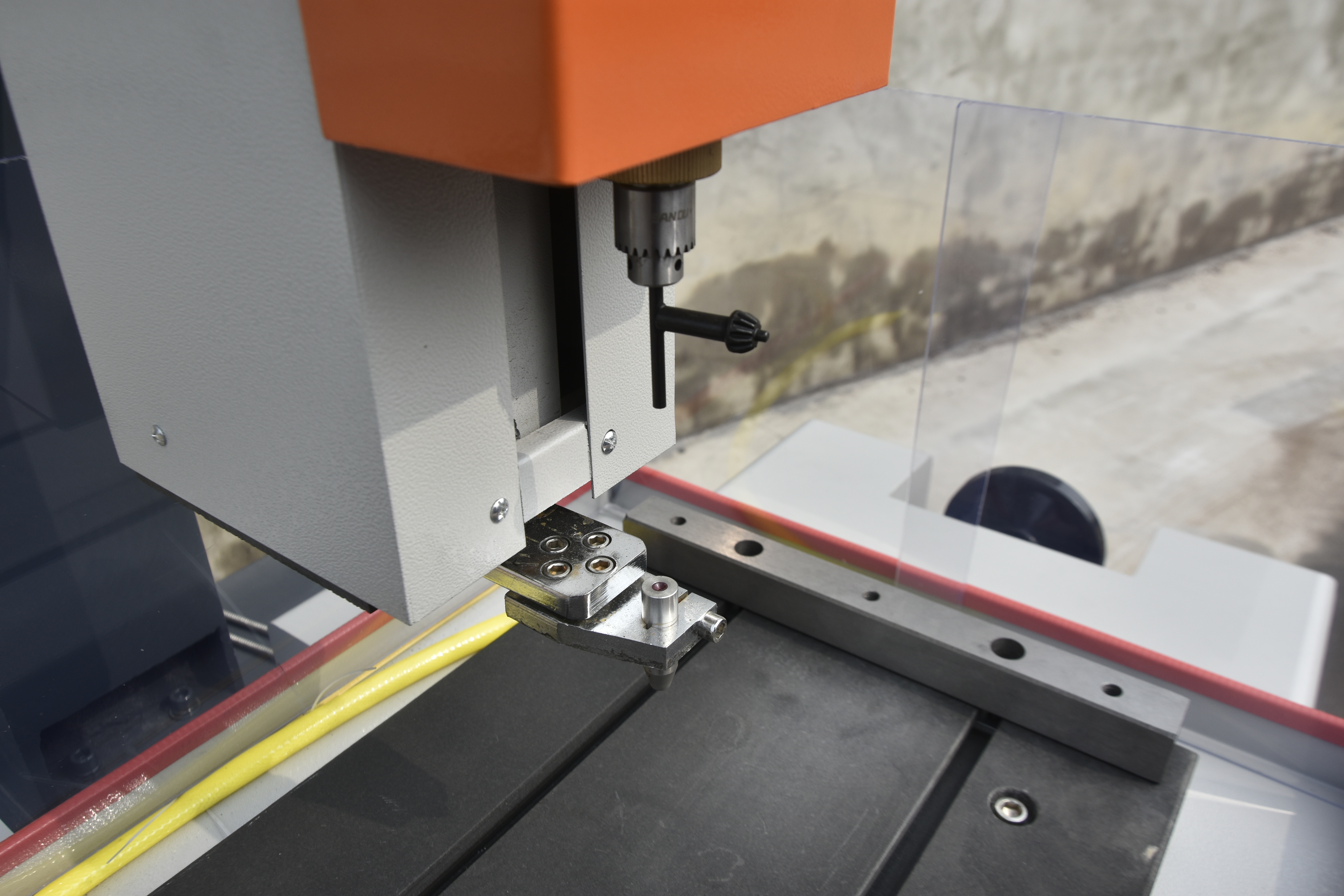

At its heart, EDM drilling relies on the principle of electrical discharge between an electrode and the workpiece. This process, known as spark erosion, occurs in a dielectric fluid environment. When electrical current passes between the electrode and the workpiece, it creates a series of controlled sparks that precisely remove material, forming the desired hole geometry.

The dielectric fluid plays a crucial role by providing insulation until sufficient voltage builds up for discharge, flushing away debris, and cooling both the electrode and workpiece. This carefully orchestrated process ensures consistent hole quality and prevents thermal damage to the surrounding material.

Advanced Control Systems and Precision

Modern EDM drilling systems incorporate sophisticated control mechanisms that monitor and adjust parameters in real-time. These systems regulate factors such as spark frequency, current intensity, and electrode rotation to optimize the drilling process. The result is unprecedented control over hole diameter, depth, and surface finish.

Computer numerical control (CNC) integration has further enhanced EDM drilling capabilities, allowing for automated operation and complex hole patterns. These advances have significantly improved both productivity and consistency in micro-hole creation.

Key Applications and Industry Impact

Aerospace and Turbine Manufacturing

The aerospace industry relies heavily on EDM drilling for creating cooling holes in turbine blades and combustion chambers. These microscopic holes, often arranged in intricate patterns, are crucial for maintaining optimal operating temperatures in jet engines. The ability of EDM drilling to create precise, angled holes in hard materials like nickel alloys has made it irreplaceable in this sector.

Beyond basic hole creation, EDM drilling enables manufacturers to achieve complex geometries and maintain tight tolerances that would be impossible with conventional drilling methods. This capability has directly contributed to improvements in engine efficiency and performance.

Medical Device Fabrication

In medical device manufacturing, EDM drilling facilitates the production of precise components for various applications, from surgical instruments to implantable devices. The process's ability to work with biocompatible materials while maintaining strict dimensional accuracy has revolutionized medical device production.

The technology's capability to create clean, burr-free holes is particularly valuable in medical applications where surface finish and material integrity are critical for patient safety and device functionality.

Technical Advantages and Limitations

Benefits of EDM Drilling Technology

EDM drilling offers several unique advantages over conventional drilling methods. It can process extremely hard materials without mechanical contact, eliminating issues related to tool wear and breakage. The process creates holes with exceptional straightness and roundness, while also capable of producing deep holes with high aspect ratios.

Another significant advantage is the ability to drill at angles and create multiple holes simultaneously, significantly improving production efficiency. The process also maintains consistent hole quality throughout the entire depth, a crucial factor in precision applications.

Addressing Technical Challenges

Despite its advantages, EDM drilling faces certain limitations that engineers must consider. The process speed is generally slower compared to conventional drilling methods, and the initial equipment investment can be substantial. Additionally, the electrode wear requires regular monitoring and replacement to maintain hole quality.

Material removal rate optimization remains an ongoing challenge, particularly when working with new materials or unusual geometries. However, continuous technological improvements and research are helping to address these limitations.

Future Developments and Innovations

Emerging Technologies and Integration

The future of EDM drilling looks promising with the integration of artificial intelligence and machine learning algorithms. These technologies are enabling more precise control over the drilling process and predictive maintenance capabilities. Advanced sensors and real-time monitoring systems are also improving process stability and reliability.

Research is ongoing into new electrode materials and improved dielectric fluids that could enhance drilling speed and precision while reducing environmental impact. These developments suggest a bright future for EDM drilling technology.

Industry 4.0 Integration

As manufacturing moves towards Industry 4.0, EDM drilling systems are being integrated into smart factory environments. This integration enables real-time process optimization, remote monitoring, and predictive maintenance. The result is improved efficiency, reduced downtime, and better quality control.

Digital twin technology is also being applied to EDM drilling operations, allowing for better process simulation and optimization before actual production begins. This advancement is particularly valuable for complex applications requiring multiple hole patterns.

Frequently Asked Questions

What materials can be processed using EDM drilling?

EDM drilling can process any electrically conductive material, including hardened steel, titanium, carbide, copper alloys, and exotic metals. The material's hardness does not affect the process effectiveness, making it ideal for working with super-alloys and other difficult-to-machine materials.

How small can holes be made with EDM drilling?

Modern EDM drilling systems can create holes as small as 0.1mm in diameter, with some specialized applications achieving even smaller dimensions. The minimum hole size is primarily limited by the electrode diameter and the machine's capability to maintain stability at such small scales.

What is the typical tolerance achievable with EDM drilling?

EDM drilling can typically achieve tolerances of ±0.01mm or better, depending on the application and machine capabilities. This high precision makes it suitable for the most demanding manufacturing requirements in industries such as aerospace and medical device production.