Mastering the Art of Precision: Modern Diamond Cutting Technology

The world of industrial cutting has been revolutionized by diamond cutting equipment, representing the pinnacle of precision engineering and material processing. These sophisticated machines harness the exceptional hardness of diamonds to slice through the most challenging materials with remarkable accuracy. From construction sites to manufacturing facilities, diamond cutting equipment stands as an indispensable tool in modern industry.

Today's diamond cutting equipment combines advanced technology with time-tested principles to achieve unparalleled cutting performance. The integration of computerized controls, laser guidance systems, and precision-engineered components ensures consistent results across various applications. This remarkable machinery continues to evolve, pushing the boundaries of what's possible in material processing.

Core Components and Operating Principles

Diamond Blade Technology

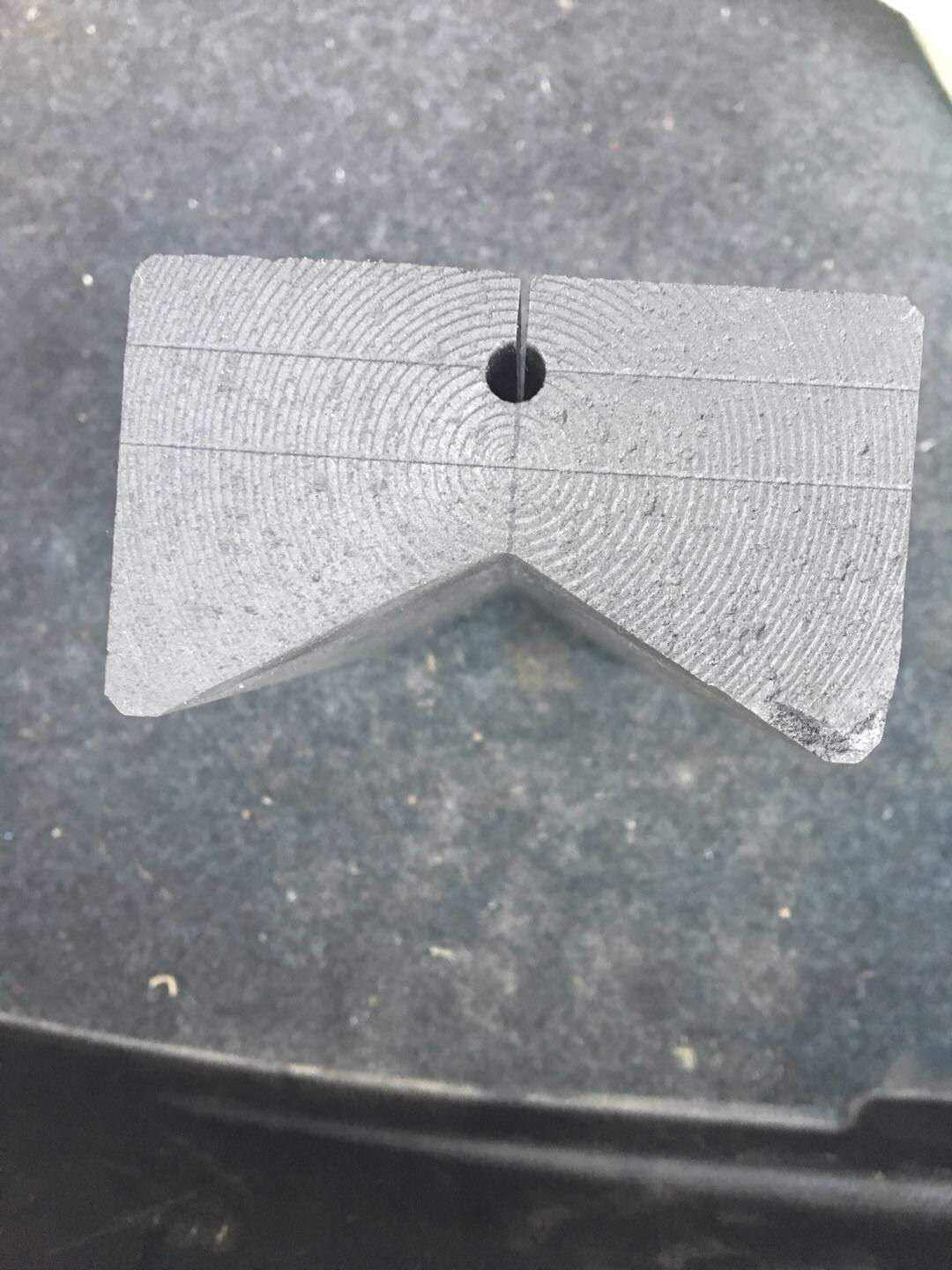

At the heart of diamond cutting equipment lies the specialized blade technology. These blades feature industrial-grade diamonds embedded in a metal matrix, creating a cutting edge that maintains its sharpness even under extreme conditions. The diamonds are strategically positioned to optimize cutting efficiency while minimizing wear on the equipment.

The metal matrix composition plays a crucial role in blade performance. Manufacturers carefully engineer this matrix to provide the perfect balance between diamond retention and controlled wear, ensuring consistent cutting quality throughout the blade's lifespan. Advanced metallurgical techniques ensure that the diamonds remain firmly anchored during operation.

Cooling and Lubrication Systems

Effective cooling is essential for diamond cutting equipment to maintain optimal performance. State-of-the-art water delivery systems provide precise cooling to the cutting zone, preventing thermal damage to both the material being cut and the equipment itself. This cooling mechanism also helps in dust suppression, creating a safer working environment.

Modern diamond cutting equipment often incorporates sophisticated fluid management systems that regulate coolant flow based on cutting conditions. These systems monitor temperature and adjust coolant delivery in real-time, maximizing cutting efficiency while minimizing resource consumption.

Applications Across Industries

Construction and Infrastructure

In the construction sector, diamond cutting equipment proves invaluable for handling reinforced concrete, natural stone, and other structural materials. These machines enable precise cuts in foundation work, renovation projects, and infrastructure maintenance. The ability to make clean, accurate cuts through steel-reinforced concrete has transformed how construction professionals approach complex projects.

Bridge repair, road maintenance, and building renovation all rely heavily on diamond cutting equipment. The precision and reliability of these tools allow contractors to complete challenging tasks efficiently while maintaining strict safety and quality standards.

Manufacturing and Precision Industries

High-tech manufacturing facilities utilize specialized diamond cutting equipment for processing advanced materials like ceramics, composites, and hardened metals. The extreme precision offered by these machines is essential for producing components that meet strict dimensional tolerances.

In aerospace and automotive manufacturing, diamond cutting equipment plays a crucial role in fabricating critical components. The ability to achieve consistent, high-quality cuts in exotic materials has enabled innovations in vehicle design and performance.

Technological Advancements and Innovation

Digital Control Systems

Modern diamond cutting equipment features sophisticated digital control systems that enhance precision and repeatability. Computer-aided cutting programs allow operators to execute complex cutting patterns with minimal manual intervention. These systems integrate with CAD/CAM software, streamlining the transition from design to production.

Advanced sensors and monitoring systems provide real-time feedback on cutting parameters, allowing for automatic adjustments to maintain optimal performance. This level of automation not only improves accuracy but also increases productivity and reduces operator fatigue.

Enhanced Safety Features

Safety innovations in diamond cutting equipment have significantly reduced workplace risks. Emergency stop systems, blade guards, and advanced dust collection mechanisms protect operators while ensuring compliance with safety regulations. Manufacturers continue to develop new safety features that maintain productivity without compromising worker protection.

Modern equipment often includes intelligent safety systems that can detect potential hazards and automatically adjust operation parameters or shut down if necessary. These preventive measures have made diamond cutting operations safer than ever before.

Maintenance and Performance Optimization

Regular Maintenance Procedures

Proper maintenance is crucial for maintaining the performance of diamond cutting equipment. Regular inspections of blade condition, cooling systems, and drive mechanisms help prevent unexpected downtime and ensure consistent cutting quality. Maintenance schedules must be strictly followed to maximize equipment lifespan and reliability.

Operators need to understand the importance of proper cleaning, lubrication, and component replacement. Training programs often emphasize these maintenance aspects to ensure equipment operates at peak efficiency throughout its service life.

Performance Monitoring and Adjustment

Modern diamond cutting equipment includes sophisticated monitoring systems that track performance metrics in real-time. These systems help operators identify potential issues before they affect cutting quality. Regular analysis of performance data enables proactive maintenance and optimization of cutting parameters.

Advanced diagnostic tools allow technicians to quickly identify and resolve issues, minimizing downtime and maintaining productivity. The integration of predictive maintenance technology helps prevent unexpected equipment failures.

Frequently Asked Questions

What materials can diamond cutting equipment process?

Diamond cutting equipment can effectively process a wide range of hard materials, including reinforced concrete, natural stone, ceramics, hardened metals, and advanced composites. The equipment's versatility makes it suitable for applications across construction, manufacturing, and precision industries.

How long do diamond cutting blades typically last?

The lifespan of diamond cutting blades varies depending on factors such as material being cut, cutting conditions, and maintenance practices. With proper use and maintenance, industrial-grade diamond blades can last hundreds of hours of operation, though exact duration depends on specific application requirements.

What factors affect cutting precision and quality?

Several key factors influence cutting precision, including blade condition, cooling system effectiveness, machine calibration, and operator expertise. Environmental conditions, material properties, and cutting parameters also play crucial roles in achieving optimal results. Regular maintenance and proper operator training are essential for maintaining high cutting quality.