- Overview

- Main Parameters

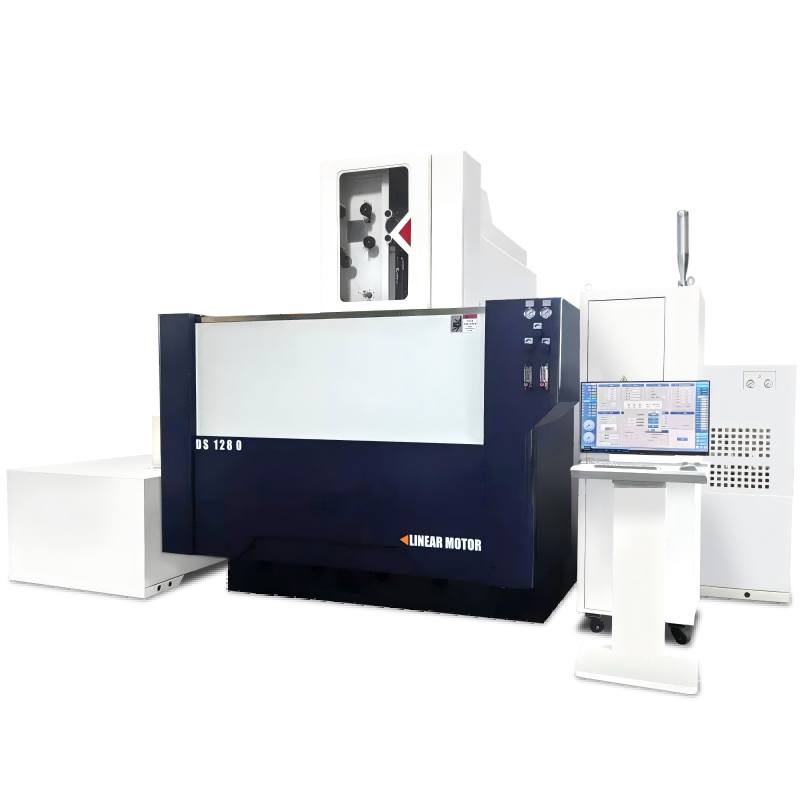

- Recommended Products

1. Main Technical Specifications of the Machine

Product Model: D703 CNC EDM Drilling Machine

| Technical parameter | |

| Machine model | DD703 |

| Table Size | 450*350mm |

| Maximum load capacity | 200kg |

| Electrode servo stroke | 360mm |

| Maximum drilling thickness | 300mm |

| Spindle rotating speed | 220rpm |

| X/Y stroke | 350*450mm |

| Distance between workingtable and guider | 300mm |

| Power supply operatingvoltage | 380Vac±550Hz |

| Minimum table movementequivalent | 0.001mm |

| Capacity of working tank | 25L |

| Max. pressure of working fluid | 10Mpa |

| Machine weight | 1300kg |

| Machine dimension | 1400x1700x2000mm |

| Drill hole diameter | 0.15-3.0(0.15 aperture can beprocessed with a thickness of 8mm) |

| Machine power | ≤3KVA |

| Total weight of machine | 900kg |

2. Documentation Supplied with the Machine

| Item | Specification | Quantity |

| User Manual (Mechanical Section) | Technical Document | 1 copy |

| Packing List | — | 1 sheet |

| Certificate of Conformity | — | 1 copy |

3. After-sales Service Terms

✦ From the date of delivery, the supplier shall provide a one-year warranty for the mechanical components. Under normal operating conditions, the supplier will be responsible for free repair and replacement of parts. However, wear parts, consumables, and tools are not covered by the warranty.

✦ After the one-year warranty period, the supplier will continue to provide necessary spare parts and offer maintenance services at a reasonable cost.

4. Training

The supplier shall provide 1–2 days of on-site operation training free of charge for 1–2 technical personnel from the customer.

| No. | Module | Training Content |

| 1 | Programming | Guidance on programming |

| 2 | Operation | - Introduction to machine structure, startup procedures, and control panel functions - Explanation on program calling and operation procedures - Key operation precautions |

| 3 | Mechanical Maintenance | 1) Introduction to mechanical structure: • X, Y, Z, W axis structures • Hydraulic and lubrication system structure 2) Common mechanical failures and maintenance |

| 4 | Electrical Maintenance | 1) Introduction to common electrical components and symbols 2) Basic electrical knowledge 3) Explanation of electrical control diagrams 4) Troubleshooting common electrical faults |

| 5 | Testing | Operation testing |

5. Description of Key Components

| Component | Origin (Manufacturer) | Remarks |

| Control System | Domestic | — |

| Mechanical Parts | ||

| Castings | Domestic | HT250 resin sand casting |

| Ball Screw Assembly | Domestic | P3 grade |

| Guideways | Wear-resistant cast iron guideways | — |

| Bearings | Harbin, China | P5 grade |

| NSK, Japan | — | |

| Electrical Parts | ||

| AC Contactor | Siemens | — |

| Relay | Omron | — |

| High-frequency Power Transistor | Imported from Japan | — |

| Transformer | Wuxi | — |

| Stepper Motor | Changzhou Songya | — |

| Others | Japan, Taiwan, Joint Ventures | — |

6. Standard Accessories

| Item | Specification | Quantity | Remarks |

| High-Pressure Pump | — | 1 set | Includes filter |

| Water Bucket | — | 2 pcs | |

| Leveling Pad | — | 4 pcs | |

| Fixture | — | 1 set | |

| Pressure Plate | — | 2 pcs | |

| T-slot Nut | M8 | 4 pcs | |

| Hex Nut | M8 | 4 pcs | |

| Fixing Studs | 75mm, 110mm, 140mm | 2 pcs each | |

| Electrode Sealing Rings | — | 1 bag | |

| Guide Bush | φ0.5, φ1.0 | 1 pc each | |

| Electrode | 0.5mm | 5 pcs | |

| Electrode | 1.0mm | 5 pcs | |

| Waterproof Cover (Table) | — | 1 set | |

| Timing Belt | 112MXL | 1 pc | |

| Timing Belt | 100MXL | 1 pc | |

| Allen Wrench | 4mm, 5mm | 1 pc each | |

| Drill Chuck & Key | — | 1 set | |

| Centering Bar | — | 1 pc |