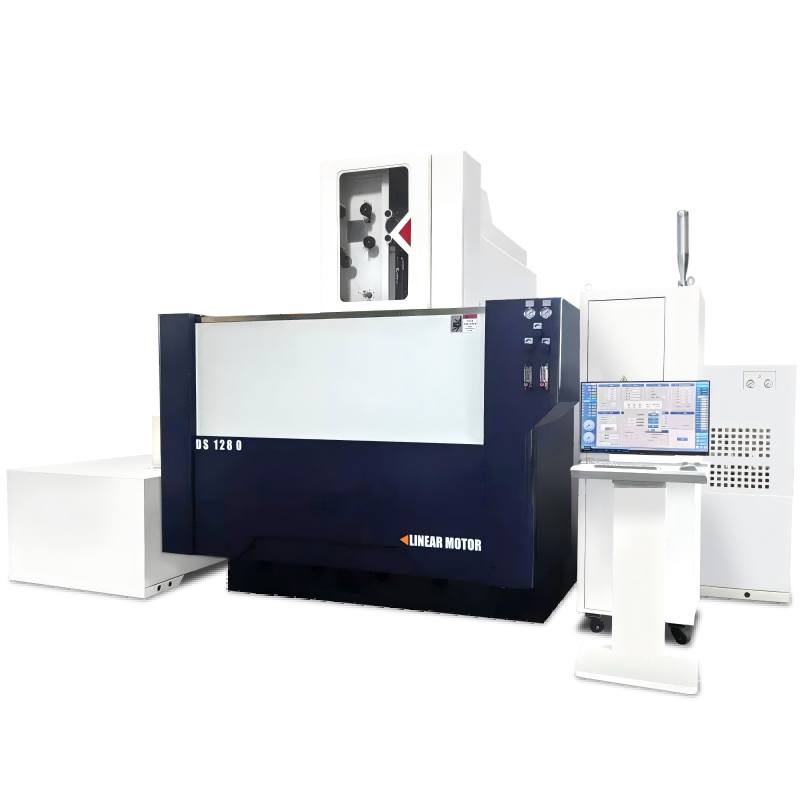

- Overview

- Main Parameters

- Control System Function

- Recommended Products

| Item | Unit | Specification |

| Travel Range | ||

| – X-axis (CNC) | mm | 1000 |

| – Y-axis (CNC) | mm | 800 |

| Worktable | ||

| – Table Size | mm | 1360 × 1030 |

| – Maximum Load Capacity | kg | 2500 |

| Maximum Cutting Taper | °/mm | 3°/6° |

| Maximum Workpiece Thickness | mm | 400 |

| Handwheel Travel per Revolution | mm | 4 |

| Optimal Surface Roughness | μm |

First Cutting: RA≤2.5

|

|

Second/Third Cutting: RA≤ 1.2

|

||

| Working Fluid System | ||

| Filtration Precision | mm | 0.005 |

| Water Tank Capacity | L | 110 |

| Working Method | Differential Pressure Filtration System | |

| Electrode Wire Diameter | mm | φ0.12 – φ0.18 |

| Maximum Wire Storage Length | m | 320 |

| Pulse Equivalent | mm | 0.001 |

| Maximum Cutting Speed | mm²/min | ≧150 |

| Power Supply Requirement | KVA | 2 (3φ ~ 380V 50Hz) |

| Operating Environment | Temperature: 10–35°C, Humidity: 3%–75% RH | |

| Maximum Machining Current | A | 8 |

| Machine Body(C Type and T Type May Differ) | ||

| – Weight | kg | 4000 |

| – Overall Dimensions | mm | 2600 × 2400 × 2050 |

| CNC Software | HL Medium-Speed Integrated CNC Control | |

| CNC Cabinet | Upright Cabinet | |

|

No.

|

Function Description

|

Remarks

|

|

1

|

Integrated programming and control software

|

|

|

2

|

Graphical tracking

|

|

|

3

|

Arbitrary angle rotation

|

|

|

4

|

Symmetrical machining

|

|

|

5

|

Wire break protection

|

|

|

6

|

Automatic shutdown upon program completion

|

|

|

7

|

USB read/write functionality

|

|

|

8

|

Four-axis coordinated cutting

|

|

|

9

|

Automatic retraction on short-circuit

|

|

|

10

|

Forward and reverse machining

|

|

|

11

|

Machining simulation

|

|

|

12

|

Power failure protection

|

|

|

13

|

Data conversion for AutoCAD DXF and ISOG formats

|

|

|

14

|

Molybdenum wire offset compensation

|

|

|

15

|

Multiple trimming cuts

|

✦ Machine Body Structure & Casting

The main body of the slow wire-cut EDM machine is built using a high-rigidity structural design and precision casting process, ensuring long-term stability and vibration resistance.

✦ Maximum Cutting Efficiency ≥150 mm²/min

The machine achieves high-efficiency performance with a cutting speed of 150 mm²/min or above, making it suitable for demanding industrial applications.

✦ Best Surface Roughness ≤ Ra 2.0 μm for One-Time Cutting

Excellent surface quality can be achieved in a single cut, reducing the need for secondary processing.

✦ Ultimate Surface Roughness ≤ Ra 0.8 μm

Through optimized parameters and multi-pass cutting, surface finishes as fine as Ra ≤ 0.8 μm are attainable.

✦ High-Precision Five-Axis Motion System

X, Y, U, V, and Z axes are all equipped with high-precision dual-nut ball screws and linear guideways from HIWIN (Taiwan), ensuring superior accuracy and durability.

✦ Precision Cutting Accuracy ≤ ±2 μm

The machine is capable of delivering exceptional dimensional precision for high-end mold and parts processing.

✦ Full Set of Japanese Imported Bearings

All bearings used in the machine are imported from Japan, ensuring long life and minimal mechanical backlash.

✦ Imported Electrical Components

Electrical components are sourced from renowned brands in Germany and Japan, ensuring reliable and consistent performance.

✦ Advanced Compensation Functions & Control System Compatibility

The control system supports pitch error compensation and backlash compensation on X, Y, U, and V axes. It is compatible with most mainstream drive software and supports manual pulse generator (MPG) operation.

✦ Encoder-Controlled Wire Travel Mechanism

The traditional mechanical travel switch is replaced by an encoder-based positioning system, enabling precise and reliable wire movement.

✦ Automatic Wire Tensioning System (Slow Wire EDM Style)

Features an advanced wire tensioning system that automatically adjusts tension according to machining conditions, ensuring consistent cutting performance and wire stability.

The machine body is constructed using high-rigidity HT300 resin sand castings, ensuring excellent structural stability and minimal vibration. Its overall design is based on the architecture of a slow wire EDM machine, providing high machining precision and operational consistency. All axes are equipped with high-precision dual-nut ball screws and ultra-precision linear guideways from HIWIN (Taiwan), ensuring smooth movement, high accuracy, and fast response. Key components incorporate imported NSK bearings from Japan, offering extended service life and exceptional reliability. The machine employs direct-drive servo motors to reduce transmission errors and supports full five-axis CNC control, enabling simultaneous interpolation on the X, Y, U, and V axes.

The self-developed electrical control system delivers fast processing speeds and superior surface finish. Advanced software functionality includes pitch error compensation for X, Y, U, and V axes, which effectively addresses accuracy issues in large taper cutting and allows for the precise machining of asymmetric upper and lower profiles. The control cabinet features a manual pulse generator for user-friendly control of all five axes (X, Y, U, V, Z) and provides real-time coordinate display for continuous process monitoring. Additionally, the system is compatible with most mainstream CNC platforms on the market, eliminating the need for extra servo or expansion cards.

The C-type machine utilizes an integrated base structure, featuring a compact design with a smaller footprint, offering advantages such as easy operation and lower cost, making it particularly suitable for processing small to medium-sized workpieces. In contrast, the T-type machine employs a tripod-shaped base structure, providing superior rigidity, stability, and load-bearing capacity, effectively ensuring the machining requirements of large or high-precision workpieces, and thus is ideal for demanding machining environments.

| Component Category | Origin (Manufacturer) | Remarks |

| Control System | ||

| CNC Controller | HF Integrated CNC / Autocut CNC | Two options available |

| Mechanical Parts(optional) | ||

| Casting Structure | Domestic | HT300 resin sand casting |

| Ball Screw Assembly | HIWIN, Taiwan | Precision Grade P3 |

| Linear Guideways | HIWIN, Taiwan | |

| Bearings | NSK, Japan / Harbin, China | |

| Electrical Parts | ||

| AC Contactor | Siemens | |

| Relays | Omron | |

| High-Frequency Power Tube | Imported from Japan | |

| Transformer | Domestic | |

| Servo Motors | Delta, Taiwan | AC Servo Motor |

| Others | Japan, Taiwan, Joint Ventures | |

In compliance with the national standard GB7926-2015‘Wire EDM Machine Tools (Reciprocating Type)–Precision Inspection’:

| Inspection Item | Specification |

| Opposite sides of a 28 mm regular octagonal prism (vertical cross-section) | 0.012 mm / 0.009 mm (after trimming) / height 40 mm |

| Opposite sides of a 28 mm regular octagonal prism (horizontal cross-section) | 0.015 mm / 0.010 mm (after trimming) / height 40 mm |

| X, Y Axis Positioning Accuracy | 0.025 mm / within 1000 mm travel |

| Repeat Positioning Accuracy | 0.013 mm / within 1000 mm travel |

| Surface Roughness (Ra) | Ra ≤ 2.5 μm / Ra ≤ 0.8 μm (after trimming) |

| No. | Accessory |

| 1 | Work Light |

| 2 | Simple Fixture |

| 3 | Electrode Wire Vertical Alignment Device |

| 4 | Hand Lever |

| 5 | Wire Tensioner |

| 6 | Working Fluid System |

| 7 | Worktable Splash Guard |

| No. | Documentation |

| 1 | Packing List |

| 2 | Factory Quality Inspection Report |

| 3 | One Copy of the System Operation Manual |

| 4 | One Copy of the Machine Tool User Manual |

✦ From the date of delivery, the supplier provides a one-year mechanical warranty. Under normal operating conditions, the supplier is responsible for free maintenance and replacement of spare parts; however, consumable parts, wear parts, and tools are not covered under the warranty.

✦ After the one-year warranty period, the supplier will provide the necessary spare parts for repairs and offer repair services at reasonable charges.

The supplier shall provide free on-site training for 1–2 technical personnel at supplier’s site, with a duration of 1 to 2 days.

| No. | Item | Training Content |

| 1 | Programming | Instruction on programming techniques |

| 2 | Operation | Introduction to overall machine structure, startup procedures, and control panel key functions |

| Program call-up, detailed operation instructions | ||

| Operational precautions and safety measures | ||

| 3 | Mechanical Maintenance | 1) Overview of mechanical structures: |

| – Structure of X, Y, Z, U, and V axes | ||

| – Hydraulic and lubrication system structure | ||

| 2) Common mechanical issues and maintenance: | ||

| – Wire breakage handling procedures | ||

| 4 | Electrical Maintenance | 1) Identification of common electrical components and symbols |

| 2) Basic electrical knowledge introduction | ||

| 3) Explanation of machine electrical control diagrams | ||

| 4) Troubleshooting of common electrical faults | ||

| 5 | Testing | Practical hands-on testing and machine operation verification |