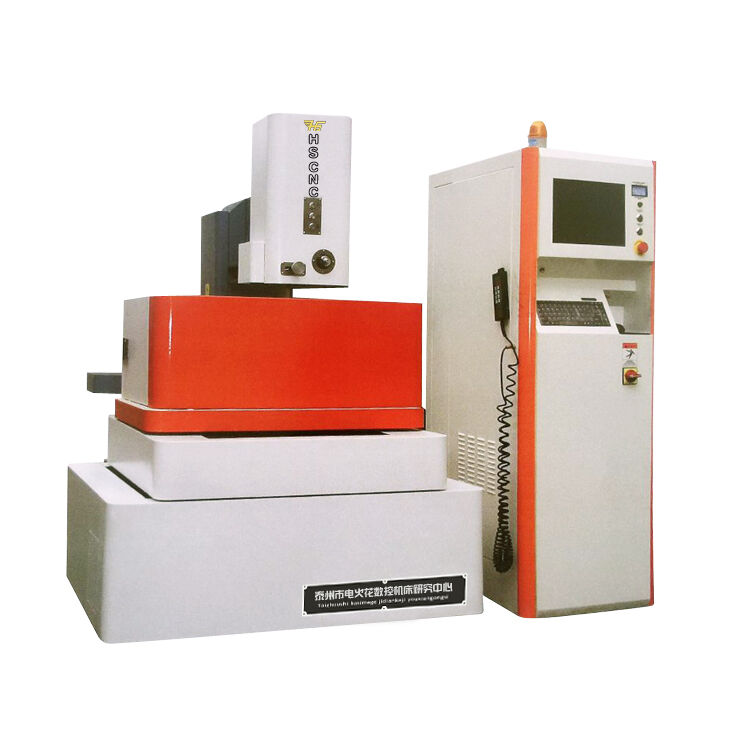

cnc edm wire cut

CNC EDM Wire Cut technology represents a revolutionary advancement in precision manufacturing, combining Computer Numerical Control with Electrical Discharge Machining principles. This sophisticated machining process utilizes a thin metallic wire as an electrode to cut through conductive materials with exceptional accuracy. The wire, typically made of brass or copper, moves along a computer programmed path while electrical discharges between the wire and workpiece create controlled erosion. This process occurs in a dielectric fluid environment which helps to flush away debris and maintain optimal cutting conditions. The technology excels in creating complex geometries and intricate shapes with tolerances as fine as .0001 inch. Its non contact cutting method eliminates mechanical stress on the workpiece, making it ideal for processing hardened materials and delicate components. The process can handle materials regardless of their hardness, provided they are electrically conductive, including tool steel, carbide, graphite, and various aerospace alloys. Modern CNC EDM wire cutting machines feature advanced control systems that enable automated operation, multi axis movement, and sophisticated cutting strategies for optimal surface finish and accuracy.