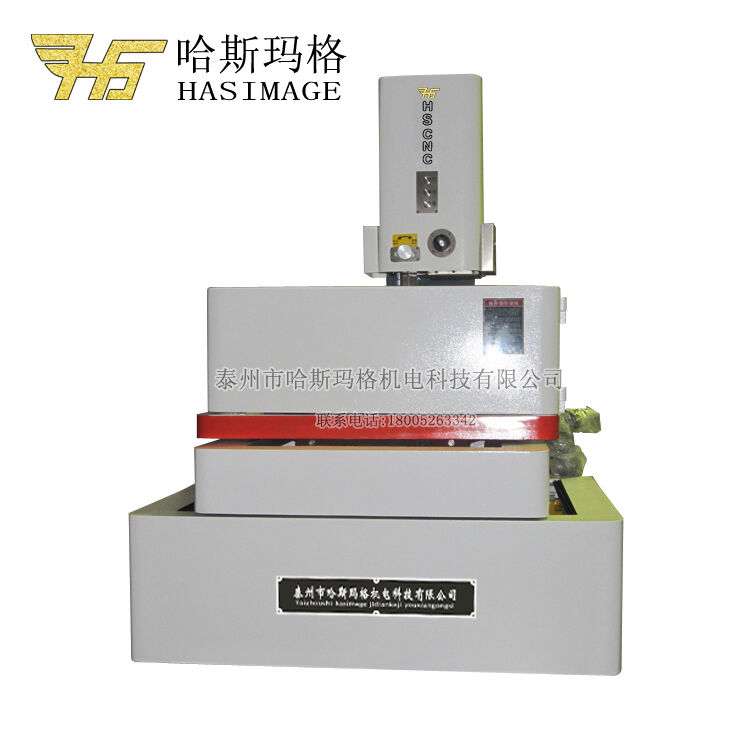

wire edm hole drilling

Wire EDM hole drilling represents a cutting-edge machining process that utilizes electrical discharge machining technology to create precise holes in conductive materials. This sophisticated method employs a brass wire electrode that generates controlled electrical sparks to erode material, creating highly accurate holes without applying mechanical force. The process excels in producing holes ranging from 0.1mm to 30mm in diameter with exceptional precision and surface finish. The technology operates by maintaining a controlled gap between the wire electrode and the workpiece while submerged in deionized water, which serves as both a dielectric medium and coolant. What sets wire EDM hole drilling apart is its ability to drill holes in extremely hard materials, including hardened steel, titanium, and carbide, with minimal heat-affected zones. The process offers unparalleled accuracy in hole positioning and roundness, making it invaluable for aerospace, medical device manufacturing, and precision engineering applications. Additionally, the technology allows for the creation of both straight and tapered holes, providing flexibility in design possibilities while maintaining tight tolerances throughout the entire depth of the hole.