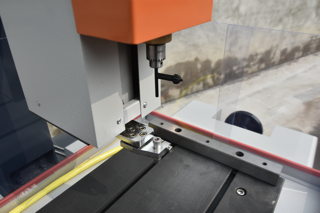

edm drilling machine made in china

The EDM drilling machine made in China represents a significant advancement in precision manufacturing technology. This sophisticated equipment utilizes electrical discharge machining principles to create highly accurate holes in various conductive materials. The machine employs a specialized electrode that generates controlled electrical sparks to erode material, enabling the creation of precise holes ranging from 0.2mm to 3.0mm in diameter. These machines are equipped with advanced CNC systems that ensure exceptional accuracy and repeatability in the drilling process. Notable features include automatic electrode wear compensation, intelligent hole-depth control, and high-speed drilling capabilities that can achieve speeds up to 300mm per minute. The machines typically incorporate a user-friendly interface with touch-screen controls, making operation intuitive and efficient. They excel in processing hard metals, including hardened steel, carbide, and other difficult-to-machine materials. The integration of advanced filtration systems ensures optimal dielectric fluid quality, while the automatic electrode guide system maintains precise positioning throughout the drilling process. These machines find extensive applications in aerospace, automotive, medical device manufacturing, and die and mold industries, where precision and reliability are paramount.