small hole edm drilling machine

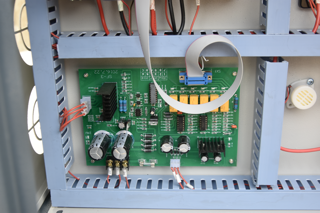

The small hole EDM drilling machine represents a pinnacle of precision engineering technology, designed specifically for creating highly accurate micro-holes in various conductive materials. This sophisticated equipment utilizes electrical discharge machining principles to achieve exceptional accuracy in hole creation, with capabilities of producing holes as small as 0.1mm in diameter. The machine operates by generating controlled electrical sparks between an electrode and the workpiece, effectively eroding material to create precise holes. Its advanced servo control system ensures consistent performance and minimal electrode wear, while the integrated cooling system maintains optimal operating conditions. The machine features a user-friendly interface that allows operators to easily program and monitor drilling parameters, including depth, diameter, and spark gap settings. Notable applications include aerospace components, fuel injection nozzles, cooling holes in turbine blades, and various precision engineering requirements in medical device manufacturing. The system incorporates high-frequency pulse generators that enable faster machining speeds while maintaining superior surface finish quality. Advanced filtration systems ensure the dielectric fluid remains clean, contributing to consistent results and extended machine life.