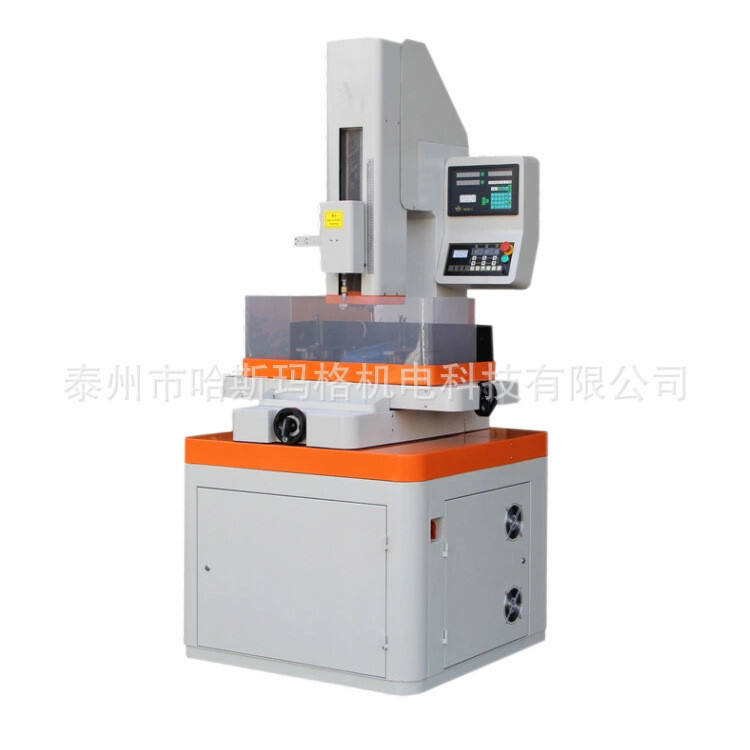

edm drilling machine price

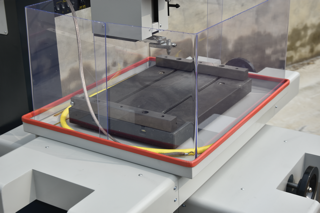

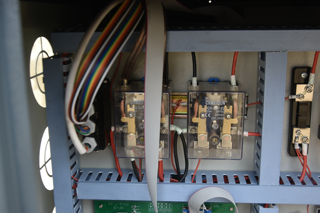

The EDM drilling machine price represents a crucial investment consideration in modern manufacturing. These sophisticated machines, utilizing electrical discharge technology, offer precision hole-making capabilities with prices typically ranging from $20,000 to $100,000 depending on specifications. The pricing structure reflects various factors including the machine's capacity, automation level, and advanced features. Entry-level models, suitable for basic manufacturing needs, start at the lower end of the spectrum, while high-end machines with advanced capabilities command premium prices. The cost consideration extends beyond the initial purchase to include operational expenses, maintenance requirements, and potential return on investment. Modern EDM drilling machines incorporate features like automatic tool changers, sophisticated control systems, and high-precision positioning mechanisms, all of which influence the final price point. These machines excel in creating precise holes in hard materials, making them invaluable in aerospace, medical device manufacturing, and precision engineering sectors. The price typically includes basic training, installation, and standard warranty coverage, though extended service packages may be available at additional cost.