edm drilling machine

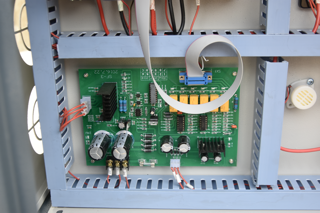

EDM drilling machines represent a cutting-edge solution in precision manufacturing, utilizing electrical discharge machining technology to create highly accurate holes in conductive materials. This sophisticated equipment operates by generating controlled electrical sparks between an electrode and the workpiece, effectively removing material through electrical erosion. The process excels in creating precise holes in hard metals and complex geometries where traditional drilling methods might fail. The machine's capability extends to producing holes as small as 0.1mm in diameter with exceptional straightness and surface finish. Advanced EDM drilling systems incorporate CNC controls, automated electrode feeding mechanisms, and precise positioning systems that ensure repeatable accuracy. The technology proves particularly valuable in aerospace, medical device manufacturing, and precision engineering industries where tight tolerances and superior finish quality are paramount. Modern EDM drilling machines feature integrated filtration systems, automatic gap control, and sophisticated power supply units that optimize the machining process. These systems can process various materials including hardened steel, titanium alloys, and carbides, making them indispensable in modern manufacturing facilities. The technology's ability to drill at angles, create deep holes with high aspect ratios, and maintain consistent hole quality throughout the process sets it apart from conventional drilling methods.