edm drilling machine manufacturers

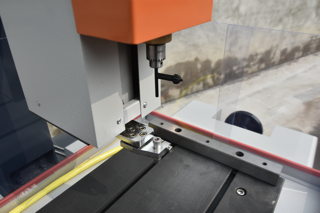

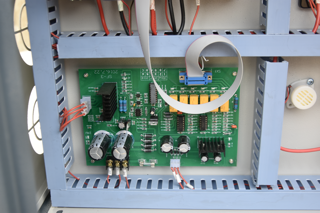

EDM drilling machine manufacturers are leading innovators in precision engineering technology, specializing in the production of advanced electrical discharge machining equipment. These manufacturers develop sophisticated machines that utilize electrical discharges to create precise holes and cavities in electrically conductive materials. Their machines excel in producing high-precision holes in difficult-to-machine materials, including hardened steel, titanium, and super alloys. The manufacturing process involves state-of-the-art CNC systems, integrated automation solutions, and advanced electrode technology. These manufacturers focus on delivering machines capable of achieving exceptional accuracy, with positioning precision often reaching micrometers. Their product lines typically include both standard and custom-built solutions, catering to various industrial applications such as aerospace, medical device manufacturing, and automotive components. Modern EDM drilling machines from these manufacturers feature advanced control systems, automated tool changers, and sophisticated cooling systems that ensure optimal performance and consistency in production. They also emphasize environmental responsibility by incorporating energy-efficient technologies and sustainable manufacturing practices in their production processes.