edm drilling machine for sale

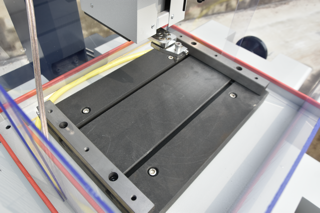

The EDM drilling machine for sale represents cutting-edge technology in precision manufacturing, offering unparalleled accuracy and versatility in metalworking applications. This advanced machine utilizes electrical discharge machining technology to create precise holes in conductive materials, including hardened steel, titanium, and various aerospace alloys. The system employs a specialized electrode that generates controlled electrical sparks to efficiently remove material, enabling the creation of holes as small as 0.1mm in diameter with exceptional precision. The machine features a sophisticated CNC control system that ensures consistent performance and reliability across multiple operations. Its robust construction includes a stable base structure that minimizes vibration, contributing to enhanced accuracy during operation. The integrated cooling system maintains optimal temperature control, while the automatic electrode guide system ensures precise positioning and reduced electrode wear. The machine comes equipped with an advanced filtration system that maintains the dielectric fluid's quality, essential for achieving superior surface finishes. Additionally, its user-friendly interface allows operators to easily program and monitor drilling operations, making it suitable for both experienced machinists and newcomers to EDM technology.