edm machines manufacturer

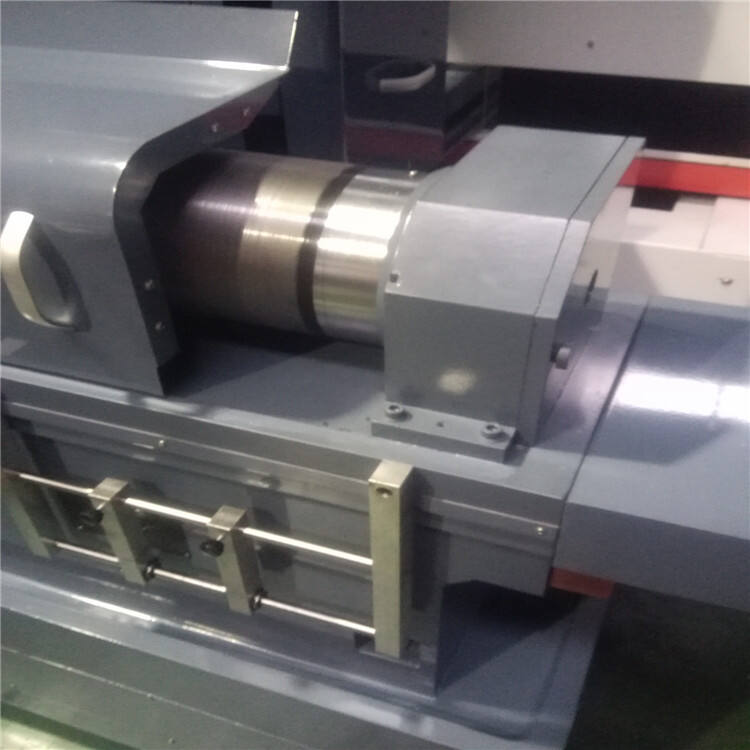

EDM machines manufacturers represent the cutting edge of precision engineering technology, specializing in the production of Electrical Discharge Machining equipment. These manufacturers develop and produce sophisticated machines that utilize electrical discharges to remove material from workpieces with exceptional accuracy. Their production facilities incorporate state-of-the-art technology to create machines capable of both wire EDM and die-sinking EDM processes. The manufacturers employ advanced quality control systems and rigorous testing protocols to ensure each machine meets precise specifications. Their facilities typically feature modern assembly lines equipped with automated systems and staffed by highly skilled engineers and technicians. These manufacturers often maintain dedicated research and development departments focused on innovating EDM technology, improving machine efficiency, and developing new applications. They provide comprehensive solutions including machine design, production, testing, and after-sales support. Many manufacturers also offer customization options to meet specific industry requirements, from aerospace components to medical device manufacturing. Their machines incorporate the latest developments in CNC technology, automated wire threading systems, and sophisticated servo control mechanisms. The manufacturing process involves careful selection of materials, precise assembly procedures, and extensive testing to ensure optimal performance and reliability. These manufacturers typically maintain global distribution networks and provide international technical support to serve customers worldwide.