edm machine shop

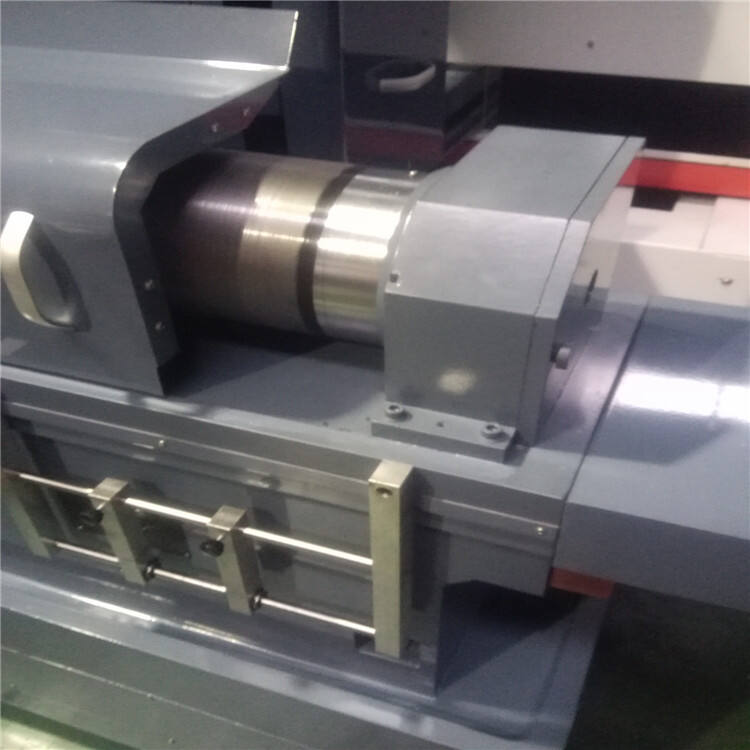

An EDM machine shop represents the pinnacle of precision manufacturing, utilizing Electrical Discharge Machining technology to deliver exceptional results in metal fabrication. These specialized facilities employ advanced EDM equipment that uses controlled electrical discharges to remove material from workpieces with unprecedented accuracy. The process excels in creating complex geometries and intricate patterns that would be impossible to achieve through conventional machining methods. Modern EDM machine shops are equipped with both wire and sinker EDM capabilities, enabling them to handle diverse manufacturing challenges. The wire EDM process uses a thin wire electrode to cut through conductive materials with extreme precision, while sinker EDM employs shaped electrodes to create precise cavities and forms. These shops typically maintain climate-controlled environments to ensure optimal machining conditions and dimensional stability. They serve various industries, including aerospace, medical device manufacturing, and tool and die production, offering capabilities for both prototype development and high-volume production runs. The combination of advanced CNC controls, automated systems, and expert operators ensures consistent quality and repeatability in every project.