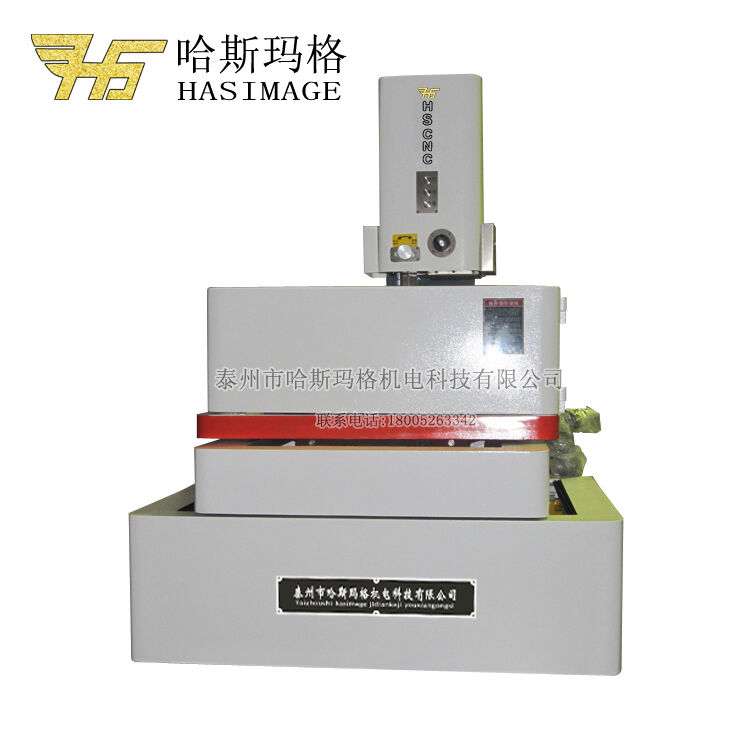

wire edm clamping system

The wire EDM clamping system represents a crucial component in precision machining operations, designed to secure workpieces during electrical discharge machining processes. This sophisticated system combines robust mechanical engineering with precise positioning capabilities to ensure optimal cutting accuracy and repeatability. The system features adjustable clamping mechanisms that can accommodate various workpiece sizes and geometries, typically ranging from small precision components to larger industrial parts. It incorporates advanced materials and design elements that maintain dimensional stability even under intense machining conditions. The system's core functionality includes multi-axis positioning capabilities, allowing for complex cutting paths while maintaining strict tolerances. Built-in alignment features ensure proper workpiece orientation, while the quick-change mechanisms facilitate rapid setup and teardown operations. The clamping system also integrates specialized insulation components to manage electrical conductivity during the EDM process, preventing unwanted discharge and ensuring precise cut quality. These systems find extensive applications across various industries, including aerospace, medical device manufacturing, and precision toolmaking, where maintaining exact specifications is paramount.