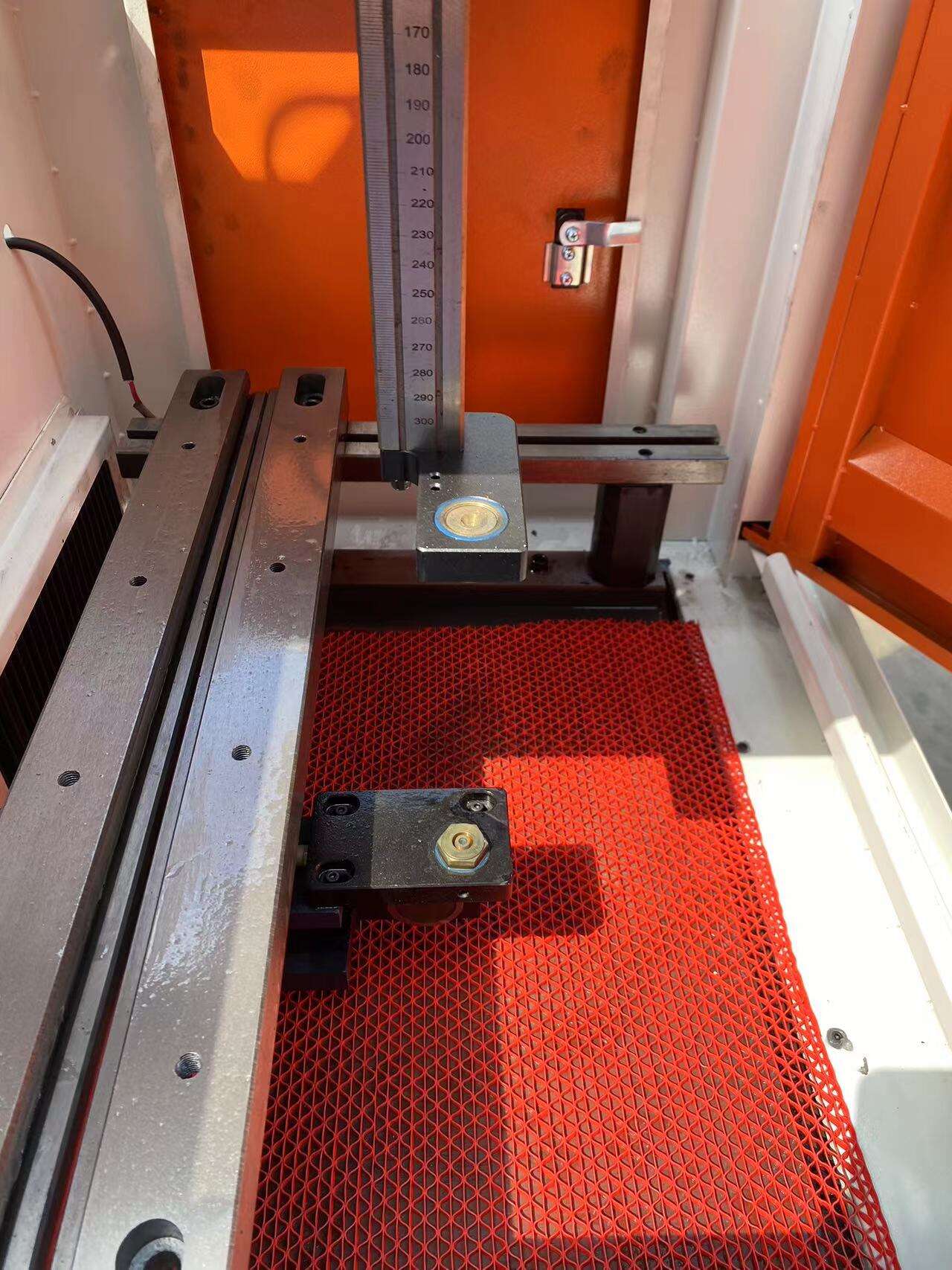

wire edm cutting machine

Wire EDM (Electrical Discharge Machining) cutting machines represent a pinnacle of precision manufacturing technology, utilizing electrical discharges to cut through electrically conductive materials with exceptional accuracy. This advanced machine employs a thin wire electrode, typically made of brass or copper, which moves through the workpiece following a pre-programmed path. The cutting process occurs through a series of controlled electrical sparks that erode the material, creating precise cuts with minimal material loss. Operating in a dielectric fluid environment, the wire EDM maintains consistent cutting conditions and removes debris efficiently. The machine's CNC control system enables complex geometrical cuts with tolerances as tight as ±0.0001 inches, making it ideal for creating intricate parts. Wire EDM technology excels in processing hardened materials, including tool steel, carbide, and aerospace alloys, which are challenging to machine using conventional methods. The process leaves no mechanical stress on the workpiece and achieves superior surface finishes. Modern wire EDM systems feature advanced features such as automatic wire threading, multi-axis control, and sophisticated programming capabilities, allowing for automated operation and complex cutting patterns. This technology finds extensive applications in mold making, aerospace components, medical devices, and precision mechanical parts.