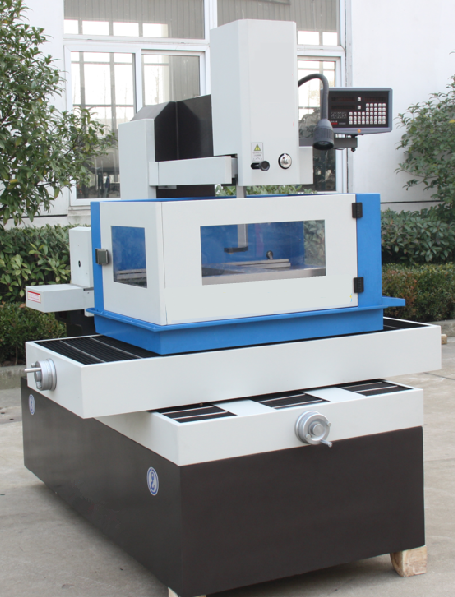

wire edm machine price

Wire EDM machine prices represent a significant investment consideration in modern manufacturing technology. These sophisticated machines, utilizing electrical discharge machining technology, offer precision cutting capabilities through electrically charged wire. Prices typically range from $40,000 to $200,000, depending on specifications, brand, and capabilities. The cost variation reflects differences in cutting speed, accuracy levels, and maximum workpiece dimensions. Entry-level machines suitable for basic operations generally fall in the lower price range, while advanced models with features like automatic wire threading, multi-axis capabilities, and superior surface finish quality command premium prices. The investment also considers factors such as power consumption, maintenance requirements, and operational efficiency. Modern wire EDM machines incorporate CNC systems, allowing for automated operation and complex cutting patterns. The pricing structure often includes installation, training, and initial maintenance packages. Additionally, manufacturers must consider ongoing operational costs, including wire consumption, dielectric fluid replacement, and regular maintenance. The return on investment typically depends on factors such as production volume, complexity of parts, and material types processed.