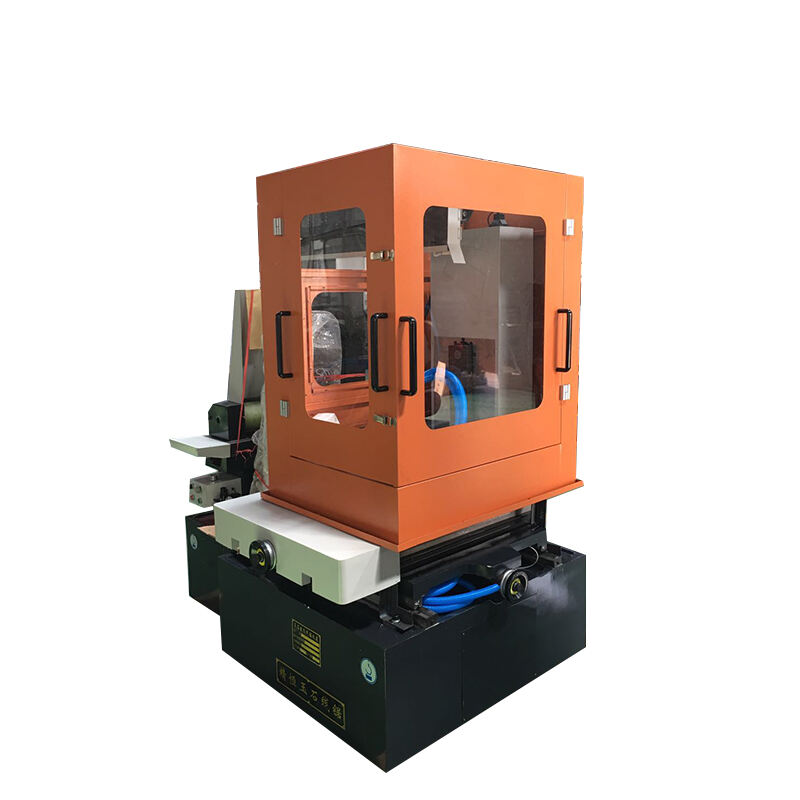

- Overview

- Main Parameters

- Recommended Products

| No. | Item | Specifications |

| 1 | Axis Travel | X-axis: 350 mm Y-axis: 450 mm |

| 2 | Worktable Size (X × Y) | 400 mm × 680 mm |

| 3 | Z-axis Feed Height | Optional: 250 mm, 400 mm, or 500 mm |

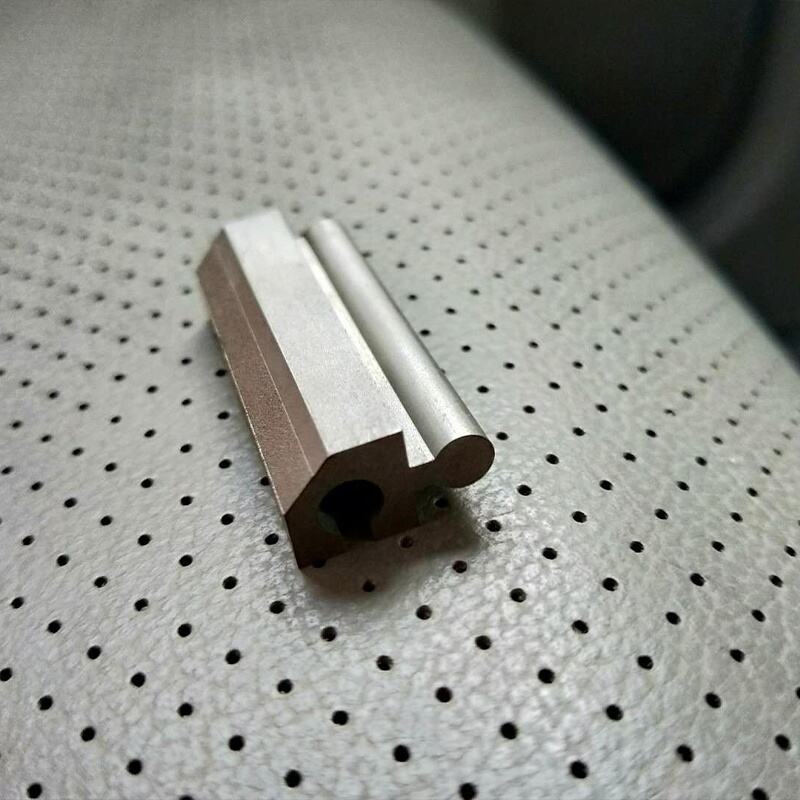

| 4 | Machining Accuracy | ±0.03 mm |

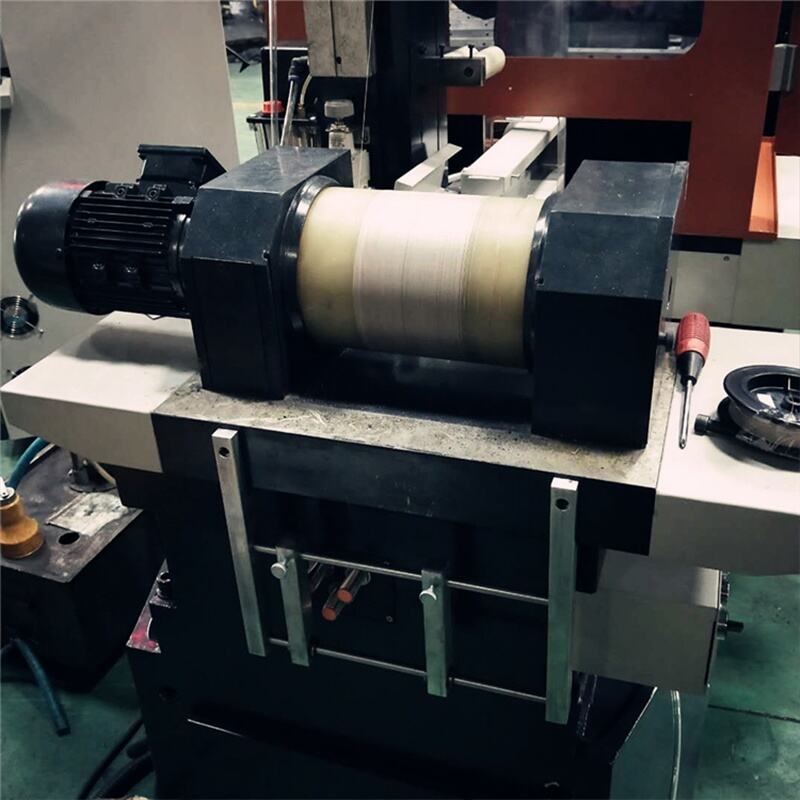

| 5 | Mechanical Structure | X and Y axes: High-precision linear guide rails and ball screws |

| 6 | Speed | Diamond wire speed: 0-11.5 m/s (adjustable) |

| Cutting speed: Depending on Materials | ||

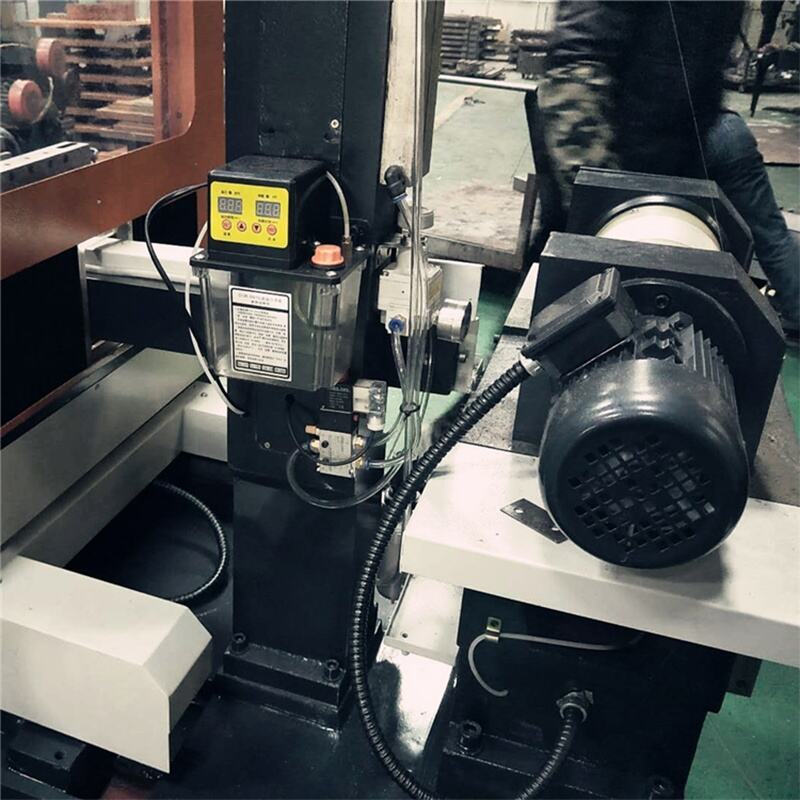

| 7 | Auxiliary Systems | Cooling Method: Water cooling |

| Lubrication: Manual lubrication system | ||

| Diamond wire diameter: φ0.12–0.45 mm | ||

| 8 | Drive System | Stepper motor with dedicated driver |

| 9 | Power Supply | AC 380V (optional 220V), 50Hz |

| 10 | Constant Tension Device | Pneumatic control via air pump |

| 11 | Supported File Formats | G-code, 3B code |

| 12 | Control System | HL CNC control system |

| 13 | Overall Dimensions (L×W×H) | 1800 mm × 1280 mm × 2100 mm |

| 14 | Machine Weight | 1400 kg |

☆ Features:

1.Designed for precision cutting and profiling of non-conductive and ultra-hard materials in small to medium thickness ranges.

2.Machine castings undergo high-temperature stress-relief treatment to ensure structural stability and machining accuracy.

3.Utilizes reciprocating diamond abrasive wire cutting, offering lower operating costs and reduced wire consumption.

4.Equipped with a precision-controlled reciprocating wire feed system, suitable for complex contour cutting and narrow workspace applications.

5.Integrated HL numerical control system, combining user-friendly programming with real-time control for efficient and accurate machining of irregular geometries.

☆ Application Materials:

Graphite, Epoxy Resin Board, Marble, Jade, Shale, Emerald, Agate, Optical Glass, Ceramics, Ferrite, Semiconductor Materials, Silicon Carbide, Refractory Bricks, Shale, Emerald, Agate, etc.

The supplier shall provide free on-site training for 1–2 technical personnel from the buyer’s side, with a duration of 1 to 2 days.

|

No. |

Item |

Training Content |

|

1 |

Programming |

Introduction to CAM programming for diamond wire cutting |

|

Usage of G-code and 3B code |

||

|

Wire diameter compensation and path offset settings |

||

|

2 |

Operation |

Overview of machine structure and components |

|

Startup and shutdown procedures |

||

|

Control panel functions |

||

|

Program loading and parameter adjustment |

||

|

Safe operation protocols |

||

|

3 |

Mechanical Maintenance |

Part 1: Structure Overview |

|

– X/Y/Z axis motion system and guide rails |

||

|

– Wire feeding and tension unit |

||

|

– Lubrication and cooling system |

||

|

Part 2: Troubleshooting |

||

|

– Diamond wire replacement |

||

|

– Guide wheel and wire path alignment |

||

|

– Handling wire breakage or jamming |

||

|

4 |

Electrical Maintenance |

Identify key electrical components and symbols |

|

Basics of electrical circuits |

||

|

Reading control cabinet diagrams |

||

|

Fault diagnosis (motor, sensor, signal issues) |

||

|

5 |

Practical Testing |

Workpiece clamping and alignment |

|

Program dry-run verification |

||

|

Actual cutting test and monitoring |

||

|

Workpiece inspection and quality evaluation |

- From the date of delivery, the supplier provides a one-year mechanical warranty. Under normal operating conditions, the supplier is responsible for free maintenance and replacement of spare parts; however, consumable parts, wear parts, and tools are not covered under the warranty.

- After the one-year warranty period, the supplier will provide the necessary spare parts for repairs and offer repair services at reasonable charges.