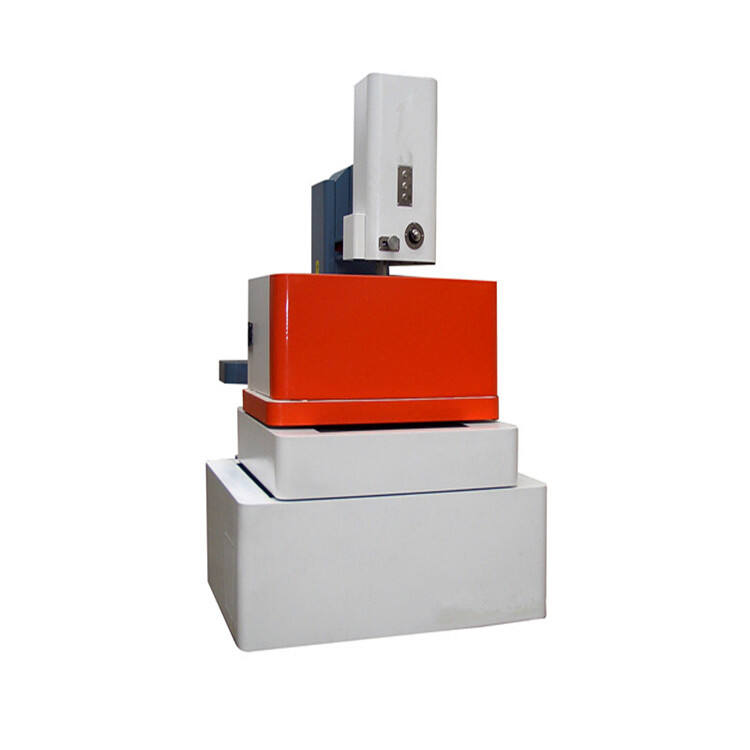

wire eroder machine

A wire eroder machine, also known as a Wire Electrical Discharge Machine (EDM), represents a pinnacle of precision manufacturing technology. This sophisticated equipment utilizes electrical discharge machining principles to cut and shape conductive materials with exceptional accuracy. The machine employs a thin metallic wire, typically made of brass or copper, which serves as an electrode to create controlled electrical sparks that erode the workpiece material. Operating in a dielectric fluid environment, the wire never physically contacts the workpiece, eliminating mechanical stress and enabling the creation of intricate shapes with superior surface finish. The machine's advanced CNC system controls the wire path with microscopic precision, allowing for complex geometrical cuts and maintaining tight tolerances down to +/- 0.001mm. Modern wire eroders feature automatic wire threading systems, multi axis control capabilities, and sophisticated programming interfaces that enable both simple and complex machining operations. These machines excel in producing precision components for industries ranging from aerospace and medical devices to tool and die manufacturing.