best wire edm

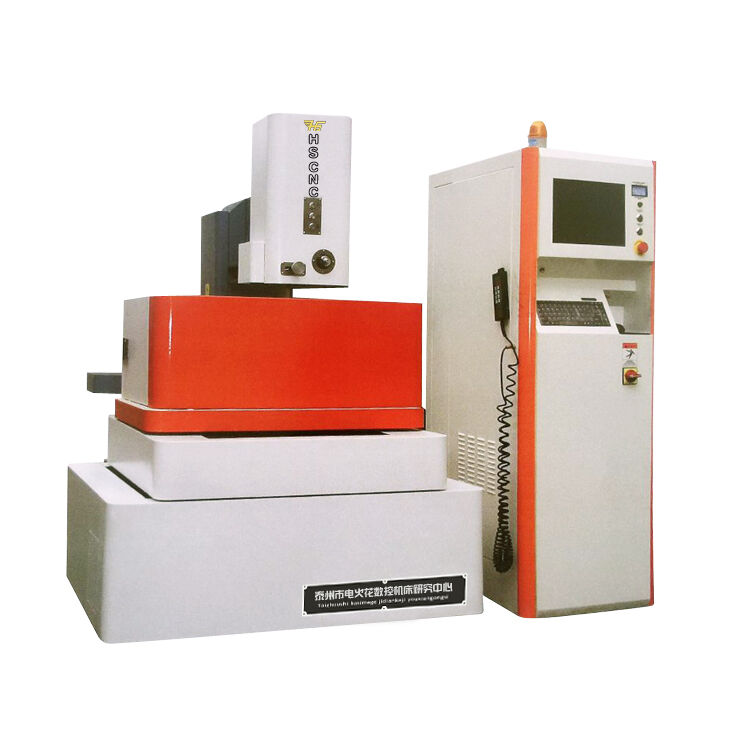

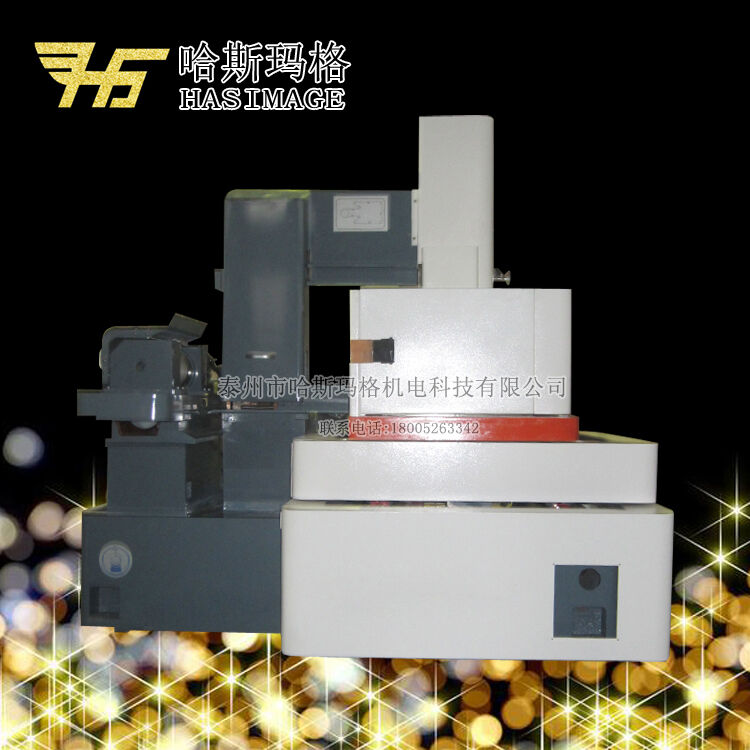

Wire EDM (Electrical Discharge Machining) represents the pinnacle of precision cutting technology in modern manufacturing. The best wire EDM systems utilize a thin metallic wire, typically brass or copper, charged with electricity to cut through conductive materials with exceptional accuracy. These advanced machines operate by creating controlled electrical discharges between the wire and the workpiece, effectively vaporizing material in a deionized water environment. The best wire EDM systems achieve positioning accuracy up to 0.0001 inches and can maintain cutting tolerances of ±0.0002 inches consistently. These machines excel in creating complex geometries in hardened materials, including specialized steels, titanium, and carbide, making them invaluable in aerospace, medical device manufacturing, and precision tooling industries. Modern wire EDM systems feature sophisticated CNC controls, automated wire threading capabilities, and advanced erosion monitoring systems that ensure optimal cutting performance. They can operate continuously for extended periods, making them ideal for high-volume production environments while maintaining consistent quality standards throughout the entire process.