- Saib xyuas

- Cov Ntsiab Lus Loj

- Cov khoom pom zoo

| TSIS MUAJ. | Khoom | Specifications |

| 1 | Lub qhov chaw ncaj nraim | X-axis: 550 mm Y-axis: 650 mm |

| 2 | Cej qhov cai (X × Y) | 610 mm × 790 mm |

| 3 | Z-axis Feed Siab | Tuaj yeem xa: 300 mm- 600 mm |

| 4 | Zog Loj Thiab Lub Raj | ±0.03 mm |

| 5 | Lub tshuab chaw | X thiab Y axes: Siab precision linear guide rails thiab ball screws |

| 6 | Ceev | Diamond wire speed: 0–11.5 m/s (adjustable) |

| Nrawm Nrawm: Txawv txawv raws li cov ntaub | ||

| 7 | Cov Ntawv Pab | Kis Txias: Kis los ntawm dej |

| Lubrication: Lub system lubrication ua tib txhab | ||

| Diamond wire diameter: φ0.12–0.44 mm | ||

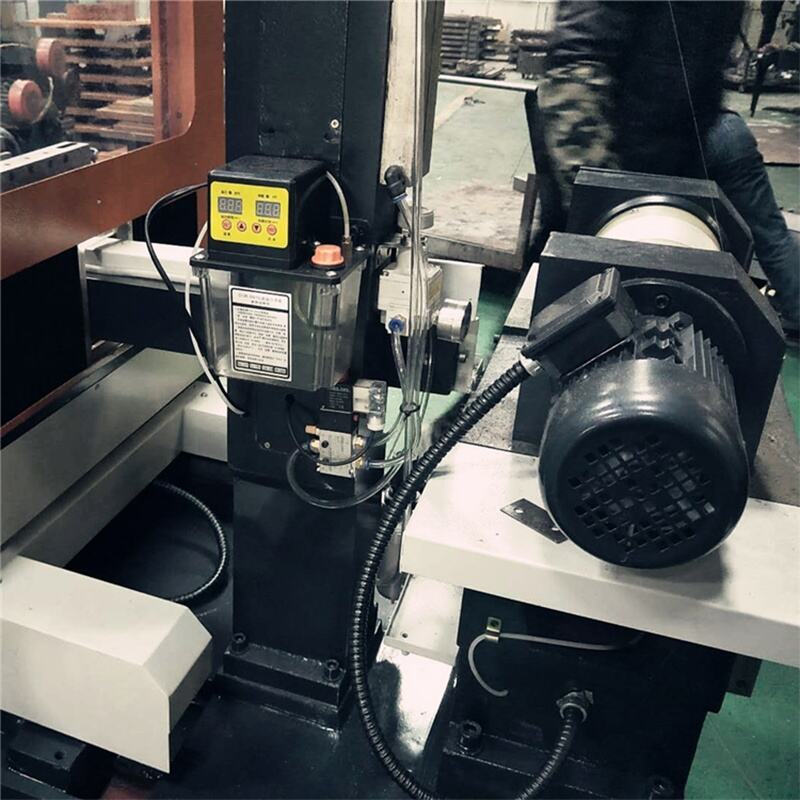

| 8 | Drive System | Stepper motor zoo li lub driver tswj |

| 9 | Tswv yim ntawm | AC 380V (tuaj yeem 220V), 50Hz |

| 10 | Cov Khoom Siv Nrawm Nrawm | Kev faib tshuab nrog cov roj teeb |

| 11 | Cov ntaub ntawv uas tau pov tseg rau kev siv | G-code, 3B code |

| 12 | Tsav Duab Lag Muag | HL CNC kev pov faib tshuab |

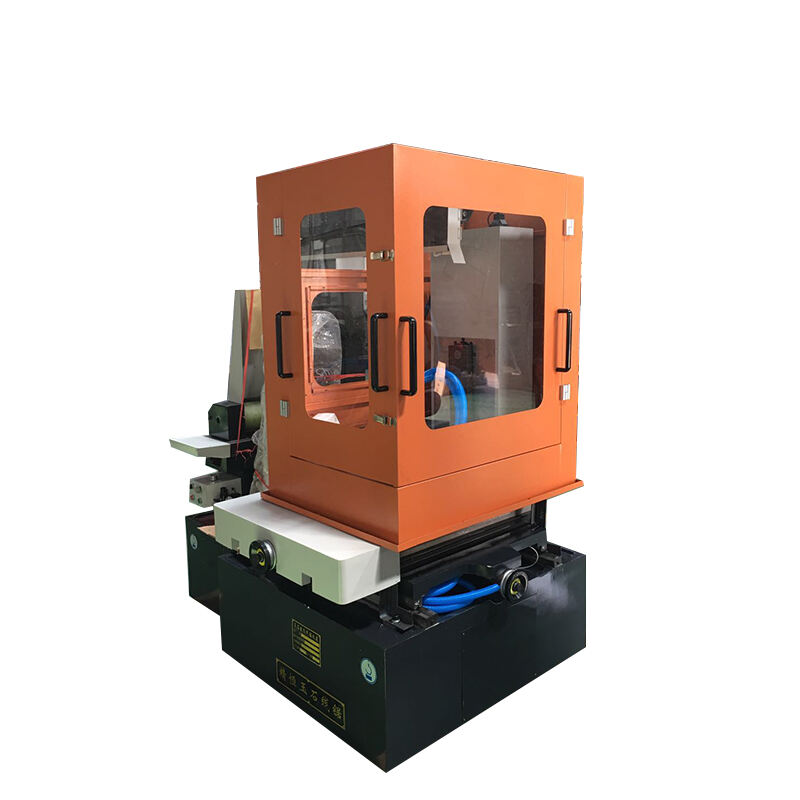

| 13 | Dav, Rois, Siab (L×W×H) | 2200 mm × 1500 mm × 2100 mm |

| 14 | Tshuab hnyav | 2100 kg |

☆ Cov Lus Qhia:

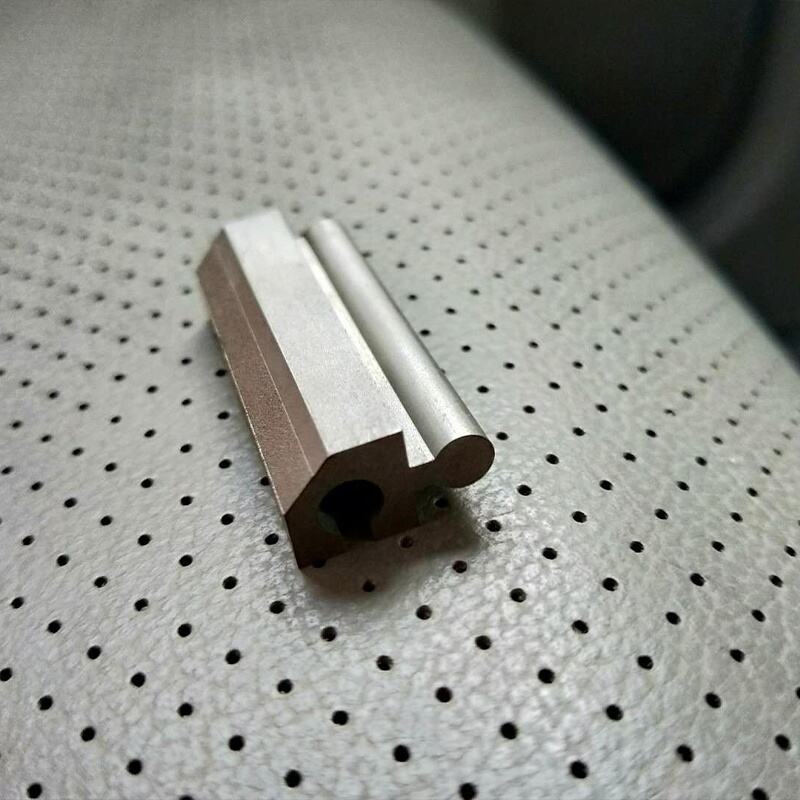

1.Txiaj rau kev muab tso tawm thiab kev kho cov ntaub uas tsis muaj hluav taws thiab cov ntaub uas nyuaj heev hauv qhov siab thiab luv.

2.Cov ntaub ntawv ua haujlwm tau txais kev txiav txim hluav taws, kom muaj kev nyob siab thiab zoo tshaj.

3.Siv cov kab nplaum uas muaj kab nplaum uas tuaj yeem tso tawm, muab kev ua haujlwm ntau dua thiab txo cov nqi thiab kab nplaum.

4.Muaj qhov chaw tso kab nplaum uas muaj kev zoo hauv kev tso tawm, zoo rau kev kho thiab kev kho qhov chaw uas muaj qhov chaw heev.

5. Qhov kev lag luam HL uas raug muab tawm los ntawm kev sau ntawv ua haujlwm nrog kev lag luam nyob rau hauv feem ntau los ntawm kev ua haujlwm zoo thiab ua haujlwm nrog cov kev lag luam ua kom zoo thiab ua kom zoo nkhaus.

☆ Lub sijhawm siv khoom:

Daim ntawv hlau, Epoxy Resin Board, Ob kauj nrog, Ntxaj, Shale, Ntxaj dua, Agate, Kev lag luam hlau, Tshav hlau, Ferrite, Khoom siv siv hluav taws, Silicon Carbide, Khoom siv hluav taws, Shale, Ntxaj dua, Agate, thiab lwm yam.

Qhov chaw muab khoom yuav tsum muab kev qhia kev paub nyob rau 1–2 tus neeg lag luam ntawm qhov chaw yuav, nrog 1 mus rau 2 hnub.

|

TSIS MUAJ. |

Khoom |

Kawm Ntawv |

|

1 |

Kawm Programming |

Kev qhia tawm rau CAM programming rau kev muab hlau |

|

Kev siv G-code thiab 3B code |

||

|

Kev kho kom zoo li cas thiab kev tswj hauv ntej |

||

|

2 |

Sib txhais |

Cov ntsiab lus ntawm lub tshuab thiab cov khoom siv |

|

Kev tswj hauv thiab kev tswj tom |

||

|

Tswv ywm kev cai ntawm qhov chaw tswj |

||

|

Kev pload program thiab kev hloov pauv cov ntaub |

||

|

Cov kev ua tiav ua hauj lwm nyob |

||

|

3 |

Kev lag luam tus me |

Qhov 1: Cov ntsiab lus txog qauv |

|

– X/Y/Z axis motion system thiab cov guide rails |

||

|

– Wire feeding thiab cov khoom hloov pauv |

||

|

– Lubrication thiab kev txias system |

||

|

Qhov 2: Cov teeb meem |

||

|

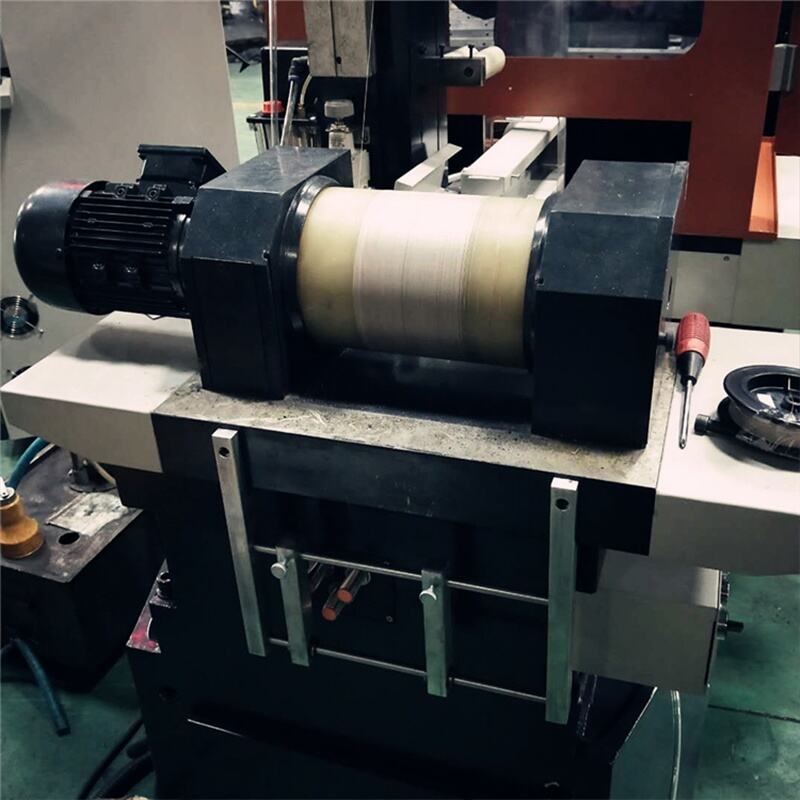

– Diamond wire replacement |

||

|

– Guide wheel thiab wire path alignment |

||

|

- Kev nres lub kaum hlua lossis lub kaum hlua tawg |

||

|

4 |

Kev lag luam hluav taws |

Txheb cov khoom siv hluav taws xob thiab cov npe ntawm cov khoom siv |

|

Cov theej xwm hluav taws xob |

||

|

Kev nyeem cov lus qhia ntawm lub khoob loj |

||

|

Kev pom cov teeb meem (cov hluav taws xob, cov khoom siv tawm, cov lus teeb meem) |

||

|

5 |

Kev test nyob rau hauv kev ua si |

Kev nres cov nta nres thiab kev ntsuas |

|

Kev tshawb xyuas cov lus qhia |

||

|

Kev test tshuaj xyuas thiab kev tswj |

||

|

Kev tshawb xyuas cov nta thiab kev tswj lub zog |

- Los ntawm lub sijhawm xa tshuab los, tus neeg muag thauj tshuab muab ib xyoos kev pab txhawb tshuab. Nyob rau hauv qhov kev siv tshuab ua tib zoo, tus neeg muag thauj tshuab yuav dhau kev saib xyuas thiab thay tshuab khoom; tab sis cov khoom siv htab, cov khoom ua haujlwm thiab cov chaw tsav tsis tau hais lus pab txhawb.

- Tom qab ib xyoos pab txhawb, tus neeg muag thauj tshuab yuav muab cov khoom siv tshuab uas xav tau thiab muab kev pab saib xyuas tshuab nyob rau hauv qhov ntau ntawm kev teev.